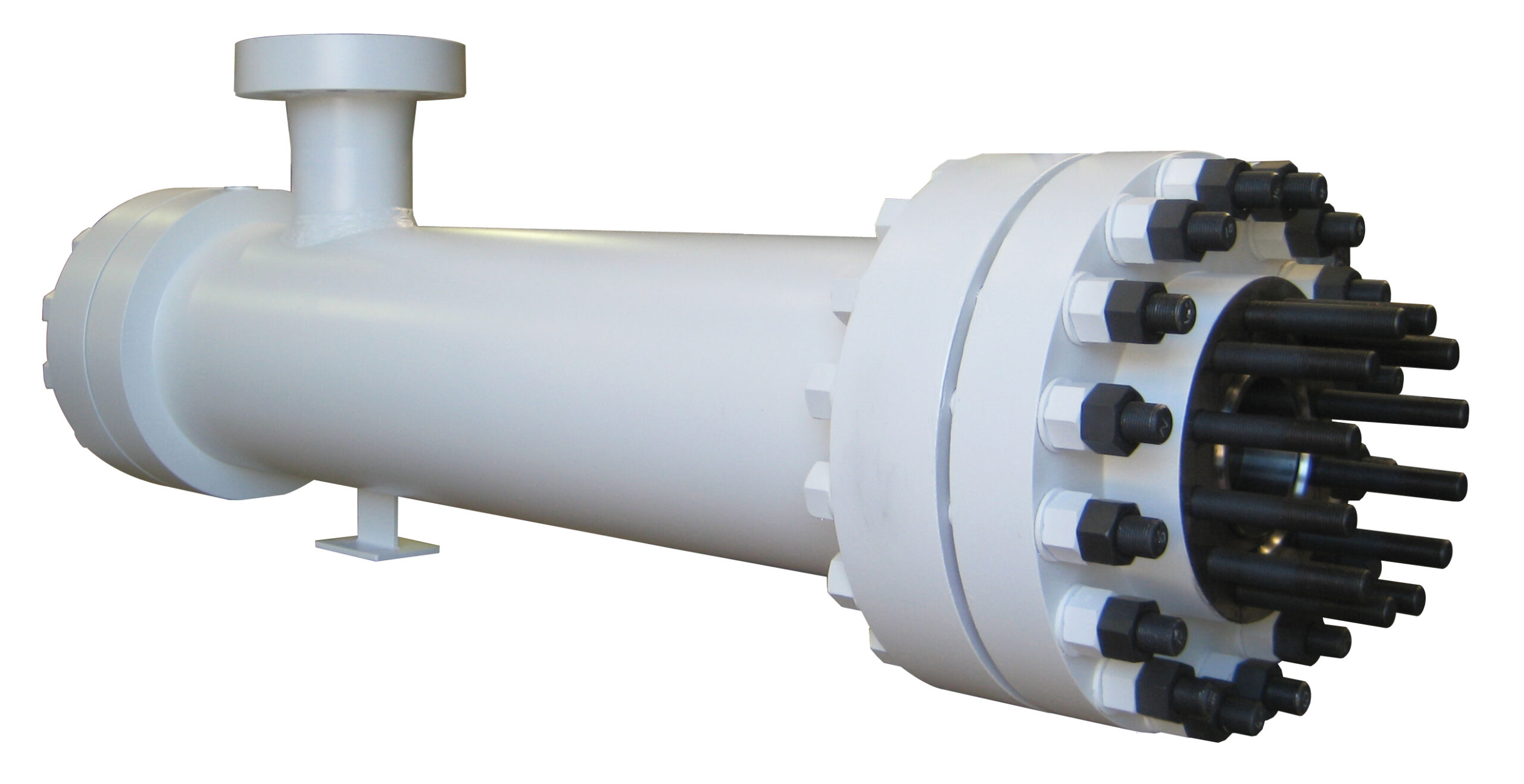

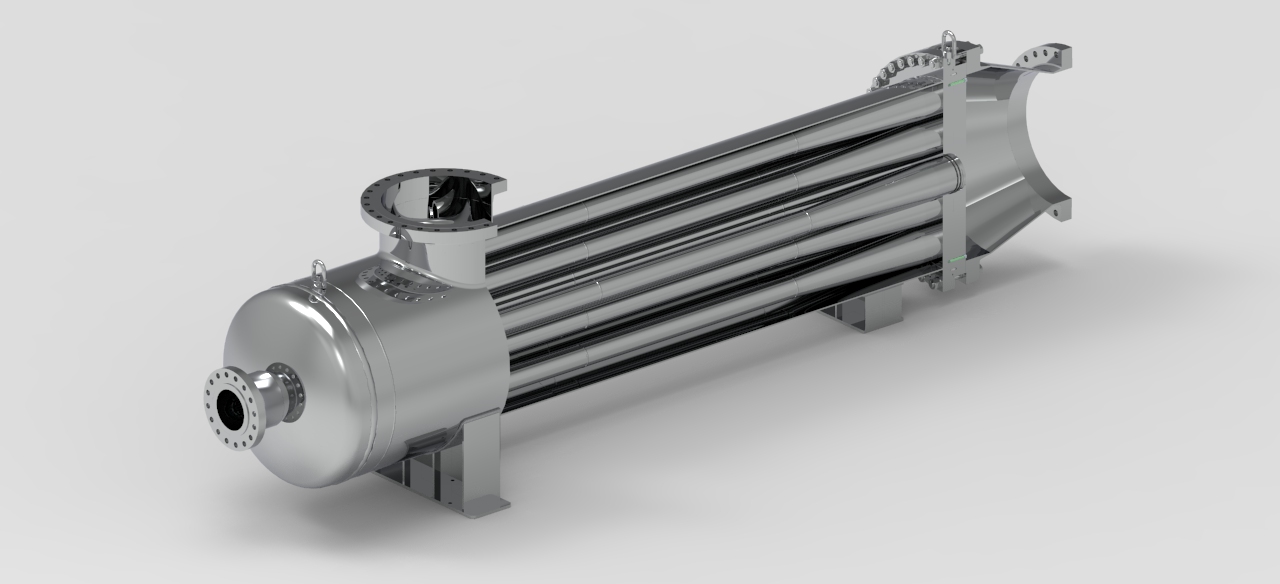

A typical Ejector contains a single-channel, with one nozzle and one diffuser. With a multi-channel Ejector, the arrangement is instead split into multiple, separate channels. These channels remain housed inside a single, common Ejector body. So, from the outside, multi-channel Ejectors look fairly similar to regular Ejectors, with 3 connections (motive, suction and discharge), but are, importantly, significantly shorter.

The primary reason for selecting a multi-channel Ejector over a single-channel Ejector is size.

Multi-channel Ejectors are significantly shorter in over-all length when compared to an equivalent single-channel Ejector. This provides a number of key benefits;

Transvac has continued to develop and improve the operating efficiency of all of our Ejectors, in particular, the range of Multi-channel designs we offer for gas compression duties.

These liquid-driven Ejectors offer high-efficiency, coupled with the practical benefits of the reduced footprint. Currently, Transvac offers multi-channel ejectors for applications such as;

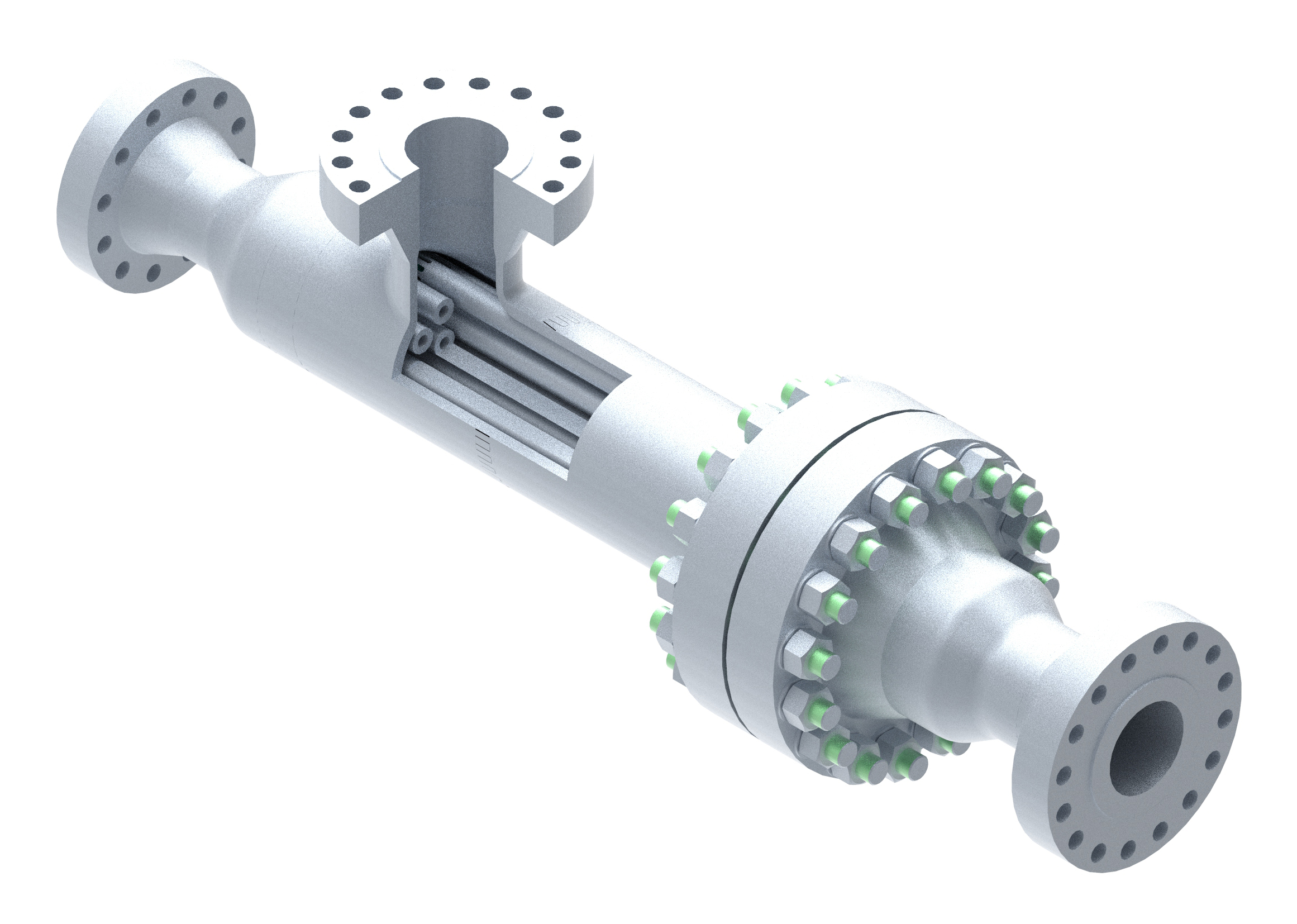

Transvac’s unique multi-channel Ejectors were initially developed in 2010, as a novel work-around to the specific challenges of a major subsea Oil & Gas project. Due to the inherent benefits of Ejector technology, such as no moving parts and no maintenance requirements – offering excellent reliability for the subsea environment – the Marlim subsea module included multiple Ejectors. However, it was not until late in the project that space constraints within one of the processing modules became apparent, meaning one of the larger Ejectors could not be accommodated.

Transvac set about redesigning the Ejector in a way that would fit into the module whilst ensuring the long-established process conditions were not affected. The multi-channel Ejector was born!

Transvac’s Research & Development Team carried out a comprehensive development programme for the new Multi-channel Ejector design. This included extensive in-house CFD simulation, with a focus on operating efficiency, to ensure that there was no loss in efficiency when moving from single to multi-channel. This was then followed by prototype testing on Transvac’s state of the art Ejector test rig to validate real-world operation.

Finally, Transvac designed and manufactured the Client’s final multi-channel Ejector, in duplex stainless steel (complete with ceramic internal parts). This was tested at full-flow conditions and was witnessed by the Client team, prior to shipment.