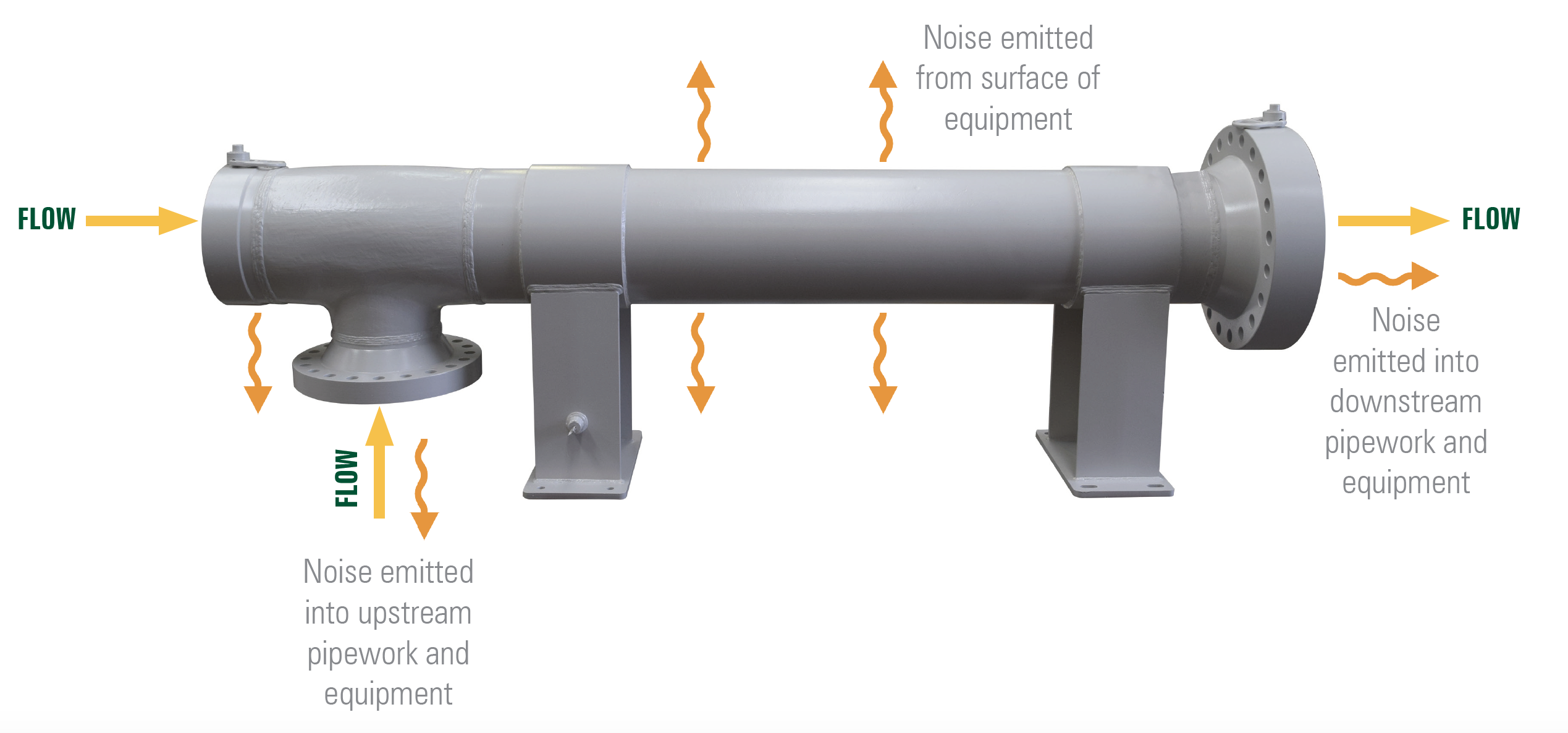

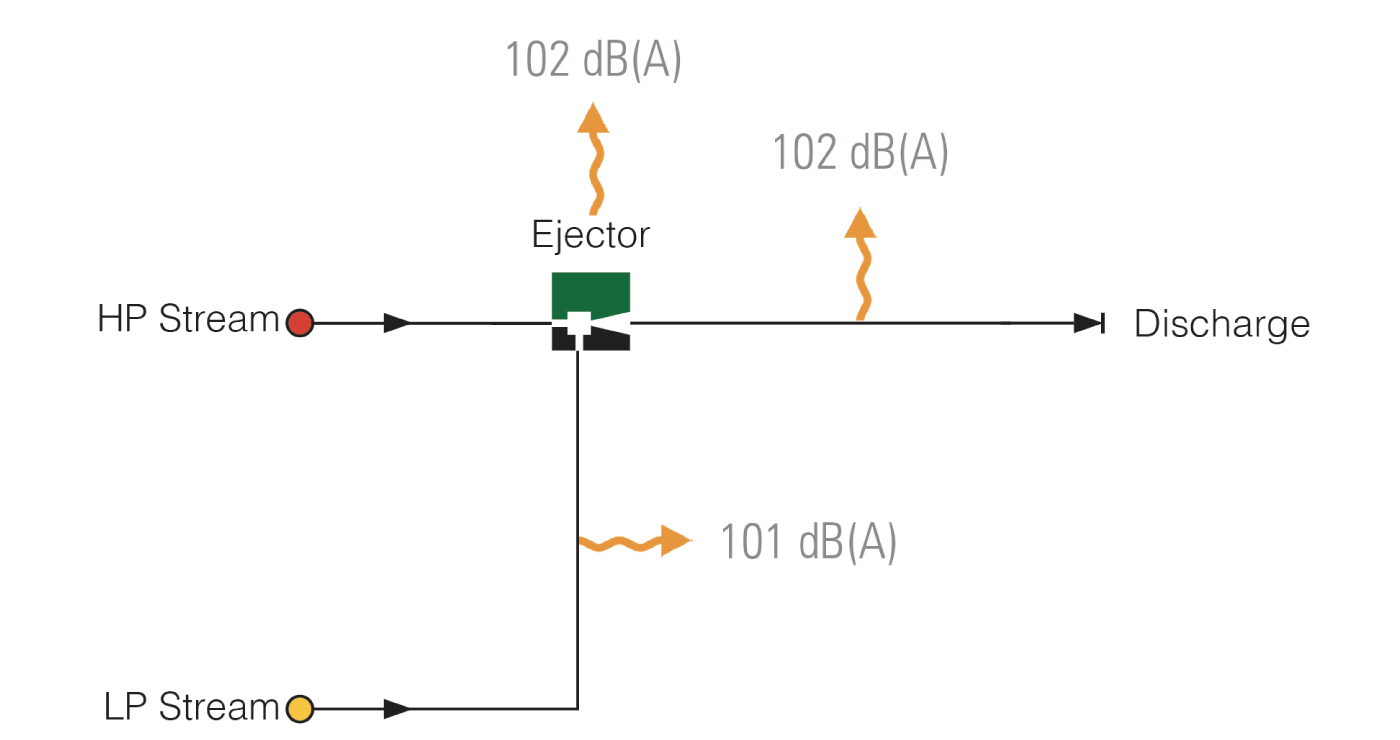

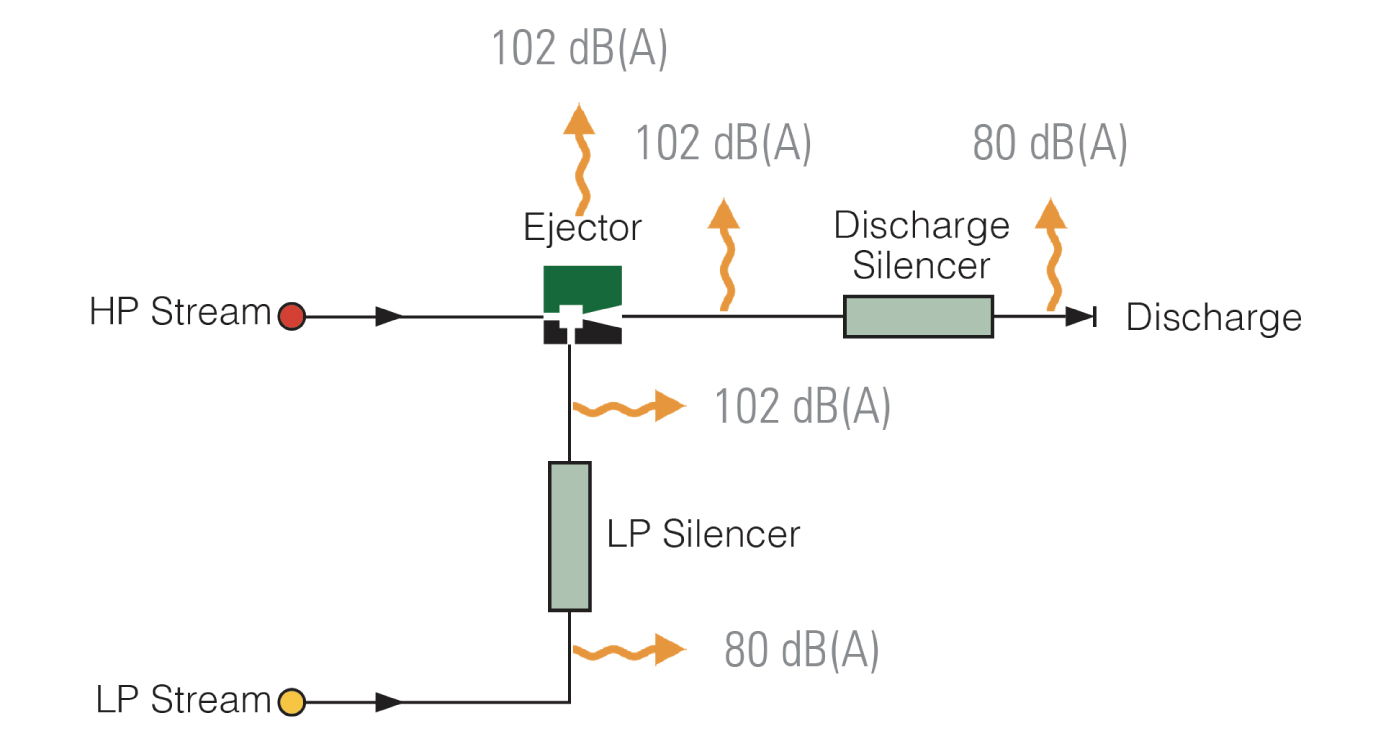

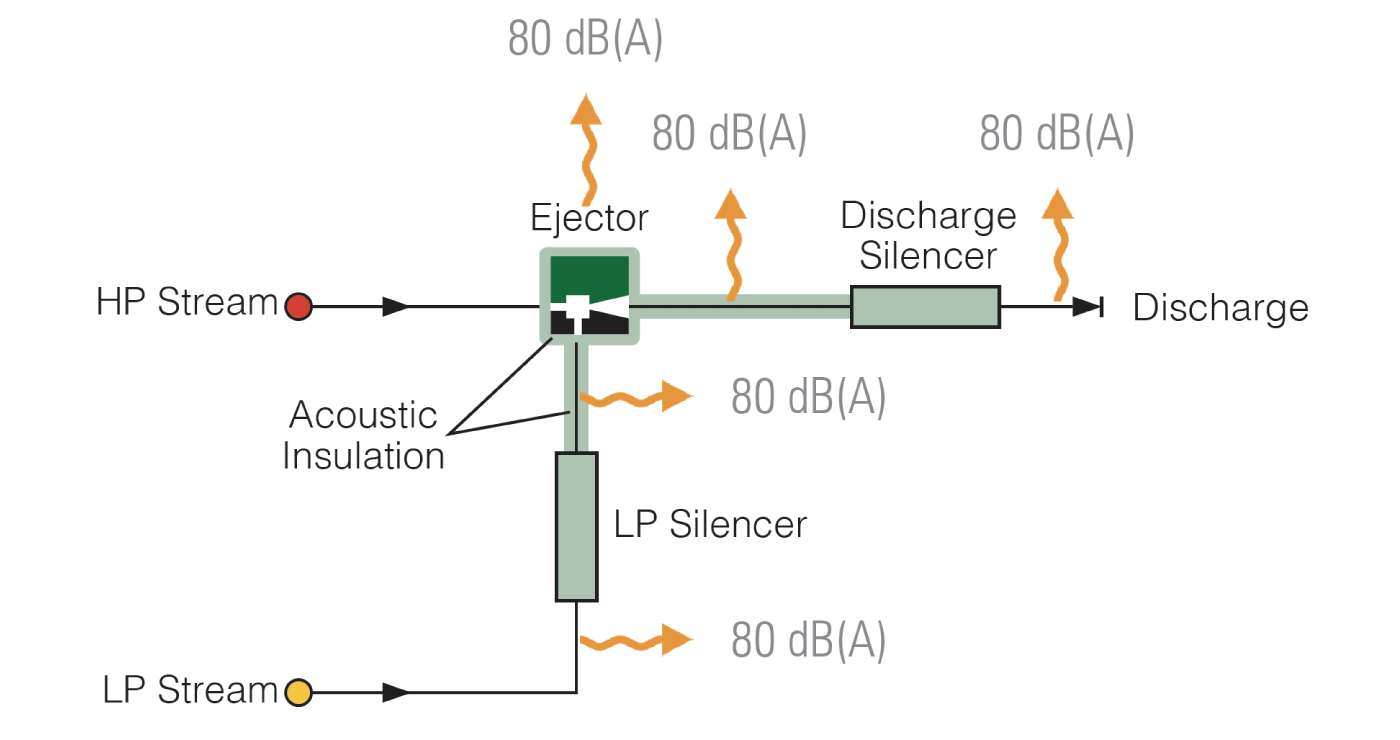

Noise can sometimes be emitted from the discharge line of the Ejector into the downstream piping system. If not attenuated, this could cause noise propagating in the downstream piping and equipment. To prevent this (and to ensure the noise emitted from the downstream piping system is within the required limit), an in-line Silencer can be installed in the Ejector discharge piping. This will prevent the onward transmission of noise into the downstream pipework and equipment.

Ideally, this Silencer would be located immediately onto the discharge connection of the Ejector, as any exposed pipework between the Ejector discharge point and the Silencer could emit excessive noise. In these cases, noise can be reduced to acceptable levels by acoustically insulating such pipework sections.

Sometimes noise can also be emitted from the suction line of the Ejector. Again, if not attenuated, this could cause noise propagating in the upstream piping and equipment. As above, the installation of a Silencer in the LP line upstream of the Ejector, together with the application of acoustic insulation of the line between the LP inlet point of the Ejector and the Silencer will reduce noise to acceptable levels.