There are various types of Ejectors that may require a performance test or a FAT (Factory Acceptance Test):

At our unique test facility in the UK, Transvac has the capability to performance test, FAT (Factory Acceptance Test) and demonstrate liquid motivated Ejectors for Flare Gas Recovery, Gas Compression, Subsea Processing, Produced Water handling and similar applications.

Many clients have witnessed performance tests at Transvac’s Test Facility including Saudi Aramco, ExxonMobil, Oxy, Equinor, Shell, Petrobras, FMCTechnip and others.

If you would like a tour of our facility, please contact us here.

Most tests are performed using water as the motive fluid and air as the suction gas, at the specified temperatures and full operating pressures for each specific application.

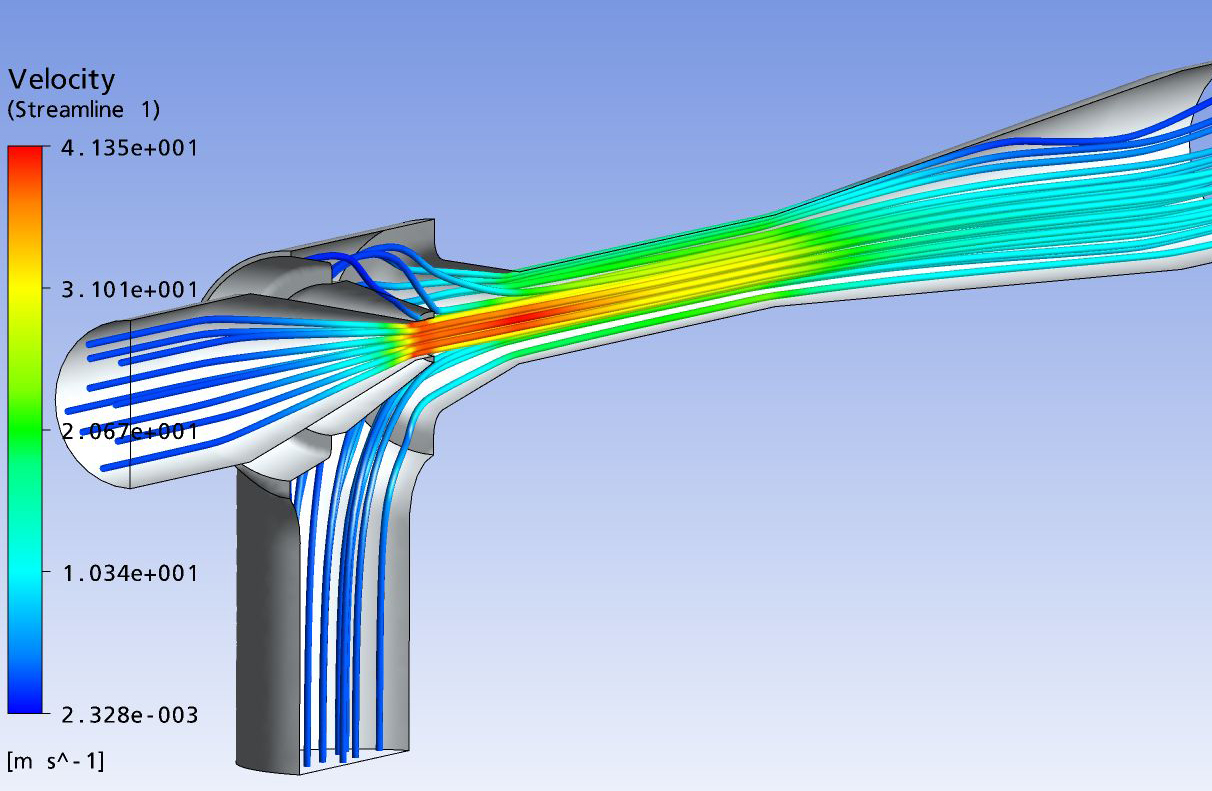

Various factors are applied, if required, to correct the resulting performance data for different fluid compositions. The methodology used for data correction has been proven by physical testing, using different fluids, operating experience all supported by CFD (Computational Fluid Dynamics) validation studies.

Transvac has the capability to test most Single-Nozzle Liquid – Gas Ejectors at full-scale liquid and gas flows. Where this is not possible, due to high flows, flow-scaled tests are performed using proven methodology.

Multi-Channel, Liquid – Gas Ejectors comprise a number of Channels (Nozzles and Diffusers) installed in a common body and are typically used for high liquid and gas flow applications.

Transvac has the capability to test one single Channel at full-scale liquid and gas flows. The performance of a complete a Multi-Channel, Liquid – Gas Ejector becomes simply the performance of a single Channel multiplied by the number of Channel installed.

Using this proven methodology, Transvac can offer performance testing of the largest Multi-Channel, Liquid – Gas Ejectors.

Because we do not have access to fluids with the same compositions and physical properties as the actual gases used for gas-gas applications, it is not possible to carry out a meaningful performance test on a Gas-Gas Ejector. The most appropriate way to performance test a Gas-Gas Ejector is to carry out a test on-site (SAT), after installation, under actual site conditions.

A “functional test” could theoretically be carried out at Transvac using air as the motive medium. However, this is not recommended because:

There is an ASME Code which covers Ejector performance tests, reference ANSI PTC 24 1976, but it does not cover cases where the actual motive gas is substituted by a different more easily obtainable test gas.

Because it is not practical to performance test Gas-Gas Ejectors, Transvac can offer as an alternative CFD (Computational Fluid Dynamic) performance test study.

The methodology used is proven and has been accepted by many clients who have found the data provided useful for design and off-design cases as well as for HAZOPs.

Please visit our CFD page here for further information.

Most tests are performed using water as the motive and suction fluid at full operating pressures for each specific application. Subsea operating pressure profiles can also be replicated.

Various factors are applied, if required, to correct the resulting performance data for different fluid compositions. The methodology used for data correction has been proven by physical testing, using different fluids, operating experience all supported by CFD (Computational Fluid Dynamics) validation studies.

Transvac has the capability to test most Single-Nozzle Liquid – Gas Ejectors at full-scale liquid and gas flows. Where this is not possible, due to high flows, flow-scaled tests are performed using proven methodology.

Multi-Channel, Liquid – Liquid Ejectors comprise a number of Channels (Nozzles and Diffusers) installed in a common body and are typically used for high liquid and liquid flow applications.

Transvac has the capability to test one single Channel at full-scale liquid and liquid flows. The performance of a complete a Multi-Channel, Liquid – Liquid Ejector becomes simply the performance of a single Channel multiplied by the number of Channel installed.

Using this proven methodology, Transvac can offer performance testing of the largest Multi-Channel, Liquid – Liquid Ejectors.

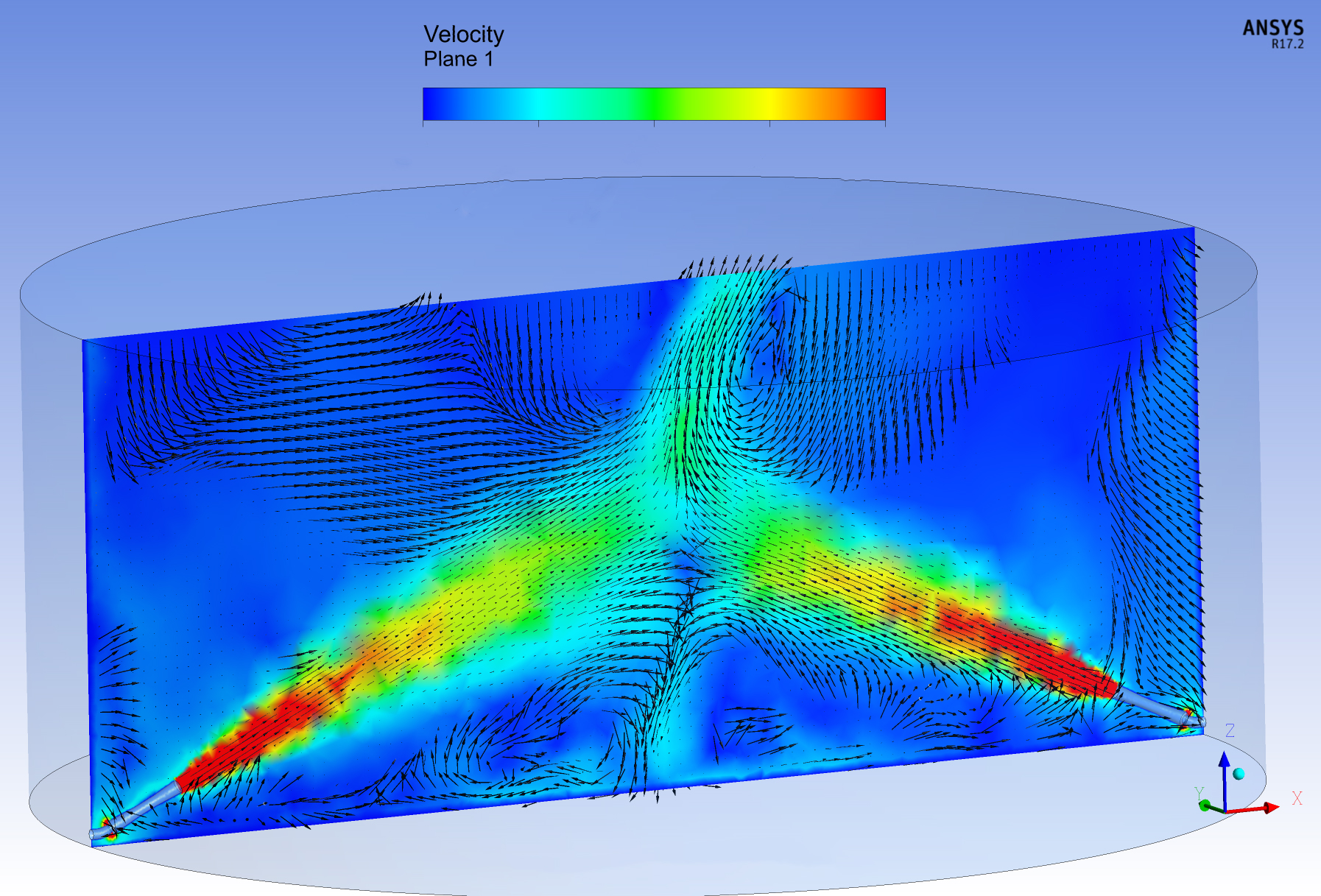

It is not practical to physically performance test Liquid-Liquid Jet Mixers because we cannot replicate the fluids involved or provide appropriate mixing Tanks.

Where the mixing quality throughout a Mixing Tank is critical to a process, for instance to achieve a certain pH level, homogeneity or temperature, Transvac can perform a CFD (Computational Fluid Dynamics) analysis to optimise a Jet Mixer System arrangement by:

Transvac has been manufacturing single and multi-stage Steam Ejectors since 1973. We have successfully suppled literally thousands of Steam Ejectors and no longer offer physical performance testing for this mature technology.

If required, as an alternative to physical testing, Transvac can offer a CFD (Computational Fluid Dynamic) performance test study. The methodology used is proven and has been accepted by many clients.

Transvac offers a service to investigate operational problems and offer solutions for all types of steam ejector systems, even they may have been supplied by another manufacturer. This service can also include training for the end users engineering staff and periodic ‘health checks’ on system performance. Learn more here.

Most multiphase Ejector tests are performed using water as the motive and suction fluid at full operating pressures for each specific application with air introduced to change the liquid-to-gas ratios.

Various factors are applied, if required, to correct the resulting performance data for different fluid compositions. The methodology used for data correction has been proven by physical testing, using different fluids, operating experience all supported by CFD (Computational Fluid Dynamics) validation studies.

Performance tests can be completed using Single-Nozzle or Multi-Channel Ejectors according to the application flow requirements.