Air Jet Ejectors

Transvac manufactures a comprehensive range of Air Ejectors also known as Air Jet Ejectors, Athmospheric Air Ejectors and Air Eductors. Air Ejectors are used to extend the operating range of Liquid Ring Vacuum Pumps, boosting performance. The inlet pressure of a Liquid Ring Pump is limited to approximately 30 mbar abs because of the vapour pressure of its seal liquid (usually water). The addition of an Atmospheric Air Jet Ejector enables the Liquid Ring Vacuum Pump to operate outside its cavitation range allowing operation down to nearly 4 mbar abs.

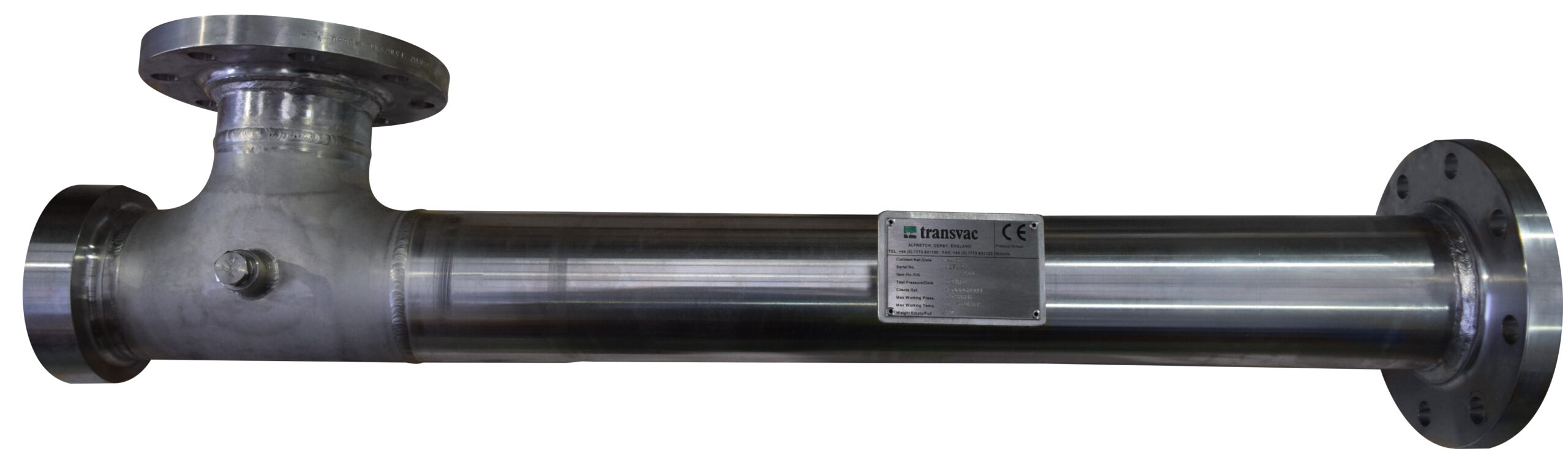

Transvac Size 4” Atmospheric Air Jet Ejector in Stainless Steel

Advantages of Air Jet Ejectors

Allows operation at higher vacuum than the liquid Ring Pump can achieve alone

No additional energy costs (motive air is free)

Custom designed to suit individual pump characteristics

No moving parts in Ejector

Virtually maintenance free

Materials to suit process

In operation, an Air Ejector uses the energy available from the expansion of atmospheric air to the Liquid Ring Pump inlet pressure. Atmospheric air enters the Ejector and passes through the nozzle where the pressure energy is converted into kinetic energy using the Venturi effect.

On leaving the nozzle at high velocity, a region of low pressure is created in the suction chamber which entrains the process fluid.

The two streams then combine within the throat of the Ejector before being decelerated in the outlet cone to recover pressure to suit the Liquid Ring Pump inlet capability.

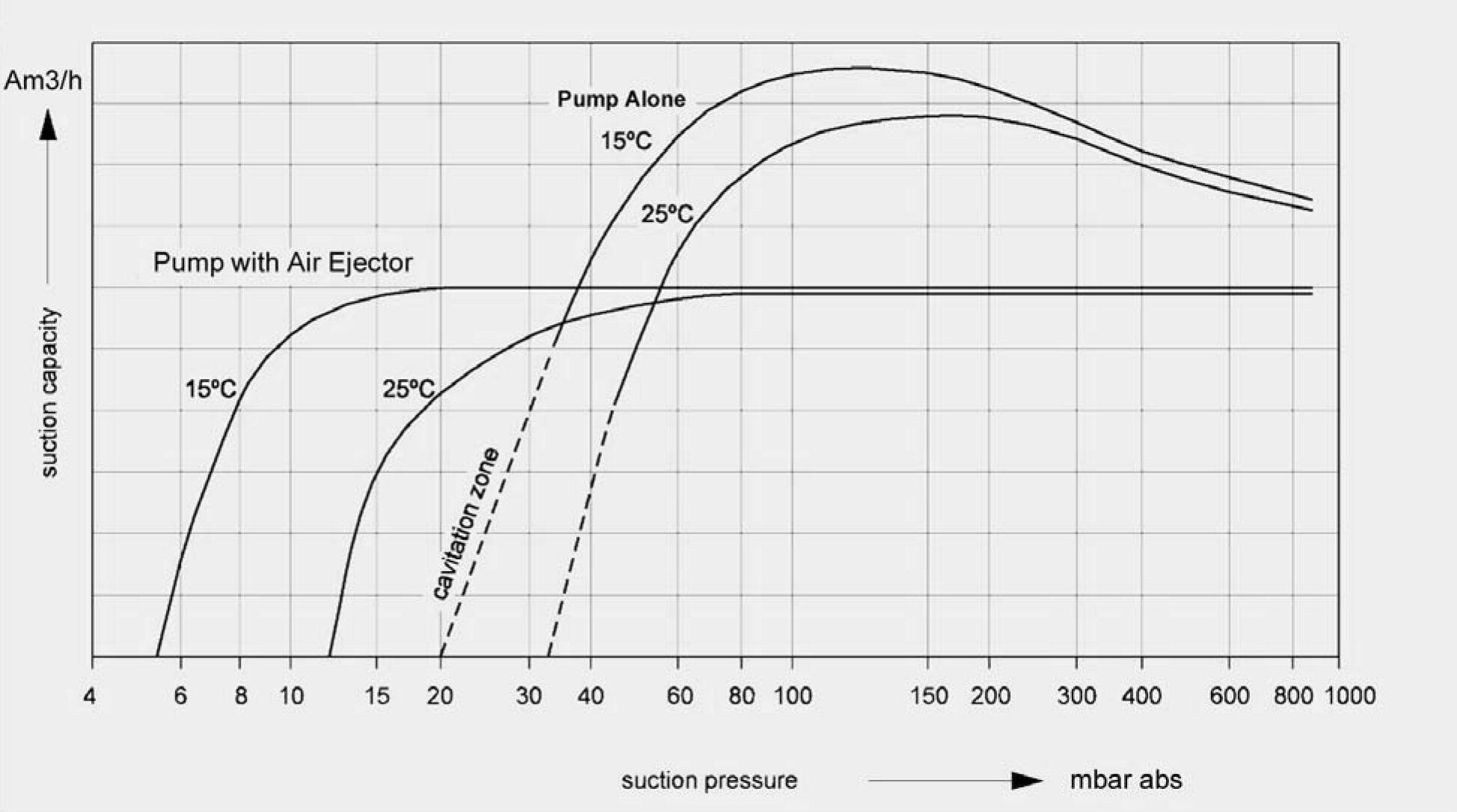

Atmospheric Air Jet Ejector Performance

The chart shows the typical performance of a 2 stage Liquid Ring Pump operating alone with seal water at temperatures of 150C and 250C and when operating in combination with an Atmospheric Air Jet Ejector. A by-pass line can be installed around the Ejector when evacuation times are critical.

All Transvac Ejectors are custom designed to suit each application to ensure maximum operating efficiency.

Although our Ejectors are suited to work in tandem with pumps, they can also effectively replace them in several applications.

Lean more how Ejectors can replace Liquid Ring Vacuum Pumps.

Materials of Construction

Standard materials of construction include Carbon Steel, Stainless Steel, Polypropylene, PTFE and Titanium. Connections can be flanged or screwed.

All of Transvac’s design and manufacturing processes are designed to the latest European standards and quality assured and certified to BS EN ISO 9001:2000. Units are CE marked where applicable.

See further information on Ejector Materials here.