Transvac direct contact steam Desuperheaters (sometimes known as attemperators) are used as a method of steam temperature control, reducing the temperature of superheated steam.

A desuperheater’s function is to produce steam temperatures approaching saturation temperature (typically to within 3°C). To cool the superheated steam, a medium, usually water, is entrained and flashed into vapour by absorbing heat from the steam.

Transvac can provide complete Desuperheating & pressure reducing stations, including control valves, temperature sensors, pressure transmitters, instrumentation and pipework, all mounted on a support skid.

For steam recovery solutions, please visit our Thermocompressors page.

Our units are available built to our own proprietary codes of practice (typically ASME B31.3) or to ASME VIII Div 1, PD5500, Stoomwezen and other recognised design codes. Units can be CE marked on request. Connections are sized to suit the process conditions. Standard materials of construction include carbon steel or stainless steel. For high temperature applications we offer chrome molybdenum steel (F11, P11, F22, P22 etc), however we can also manufacture in other metals or alloys requested.

Further information about Materials of construction can be found here.

We offer a range of Desuperheater types, to suit specific needs of your steam process;

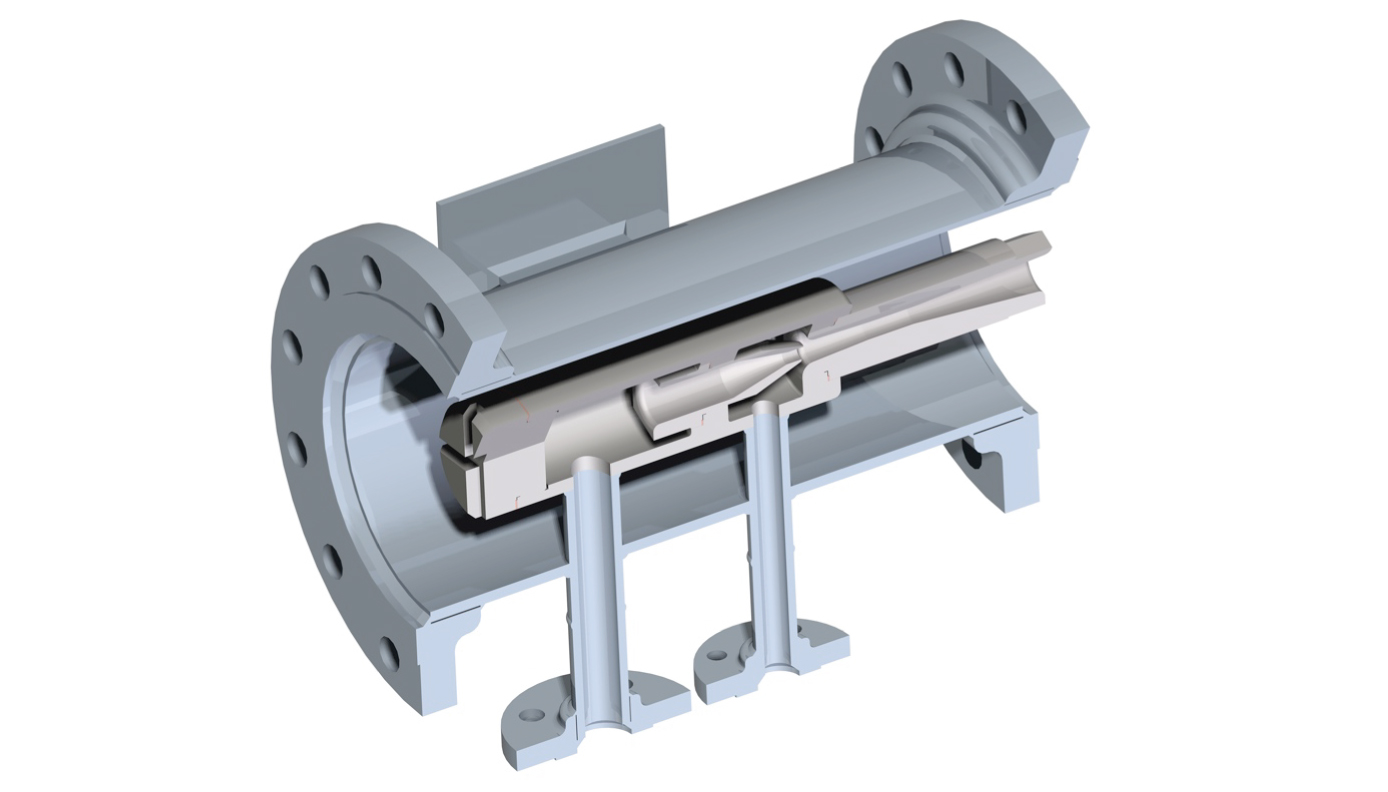

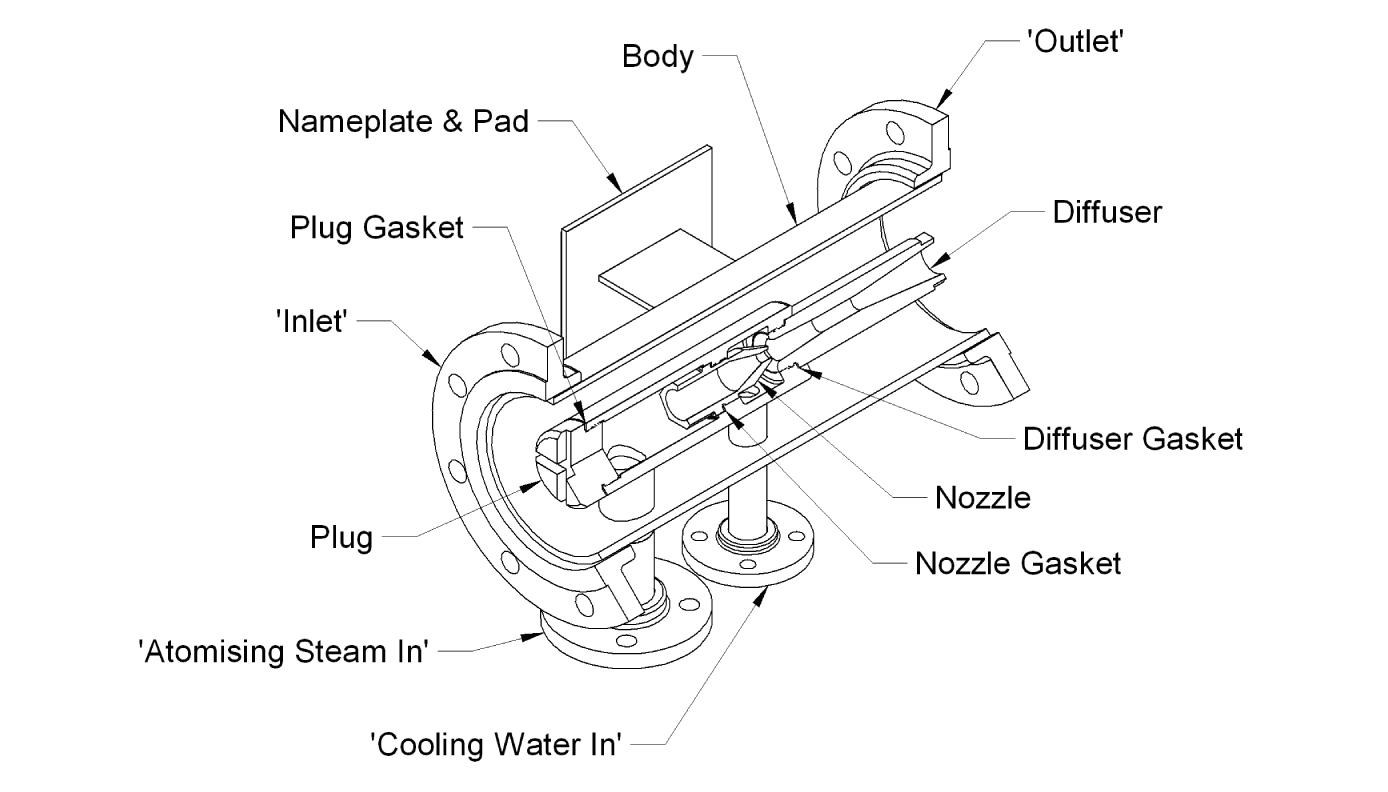

The venturi principle is used to create regions of high velocity and turbulence which produces intimate contact between the steam and cooling water.

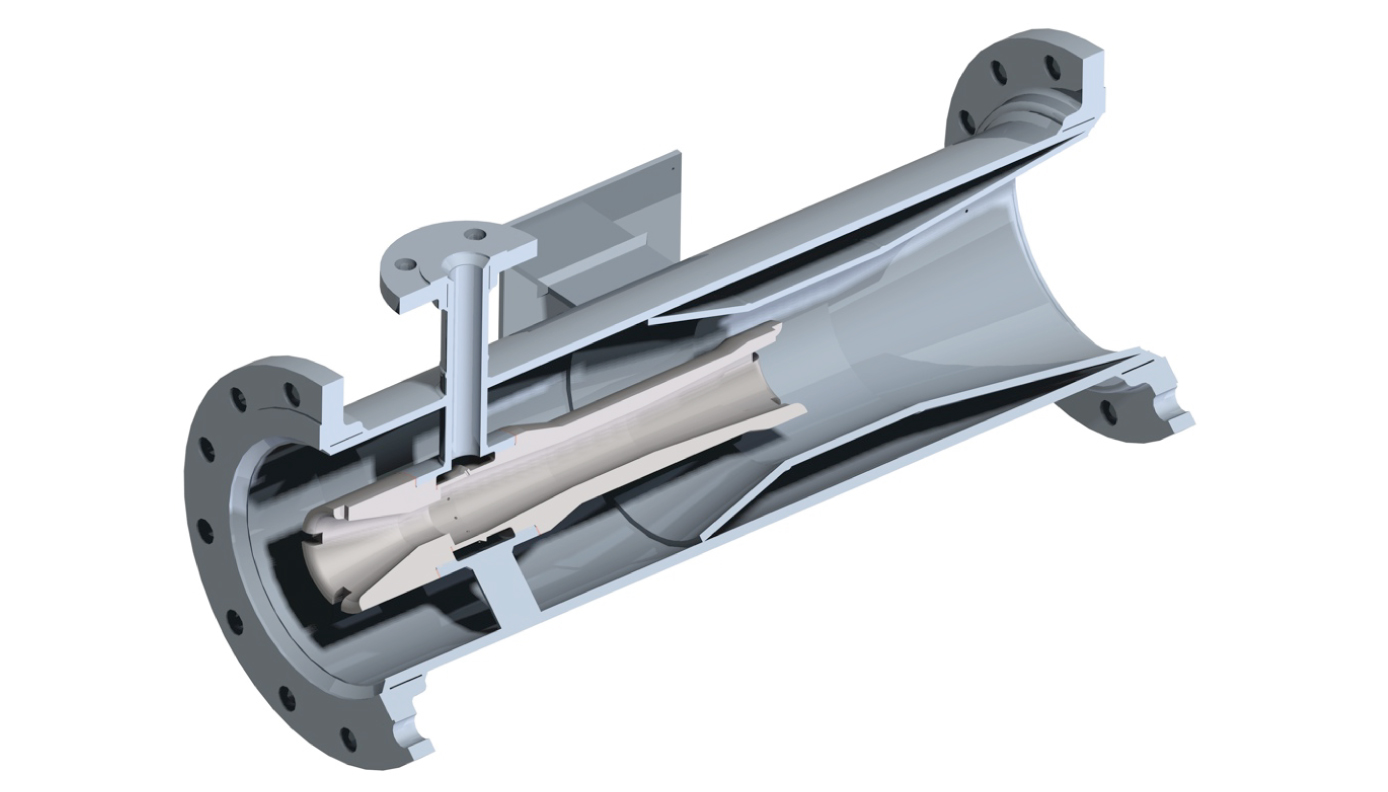

A simple in-line model where cooling water injected into the centre of the unit via an atomizing nozzle sprayed in the direction of the steam flow.

A high-pressure auxiliary steam supply is used to atomise the incoming water within the diffuser of the unit.

The venturi principle is used to create regions of high velocity and turbulence which produces intimate contact between the steam and cooling water.

Suitable for most general plant applications, except where high turndowns on cooling water are required.

A simple in-line model where cooling water injected into the centre of the unit via an atomizing nozzle sprayed in the direction of the steam flow.

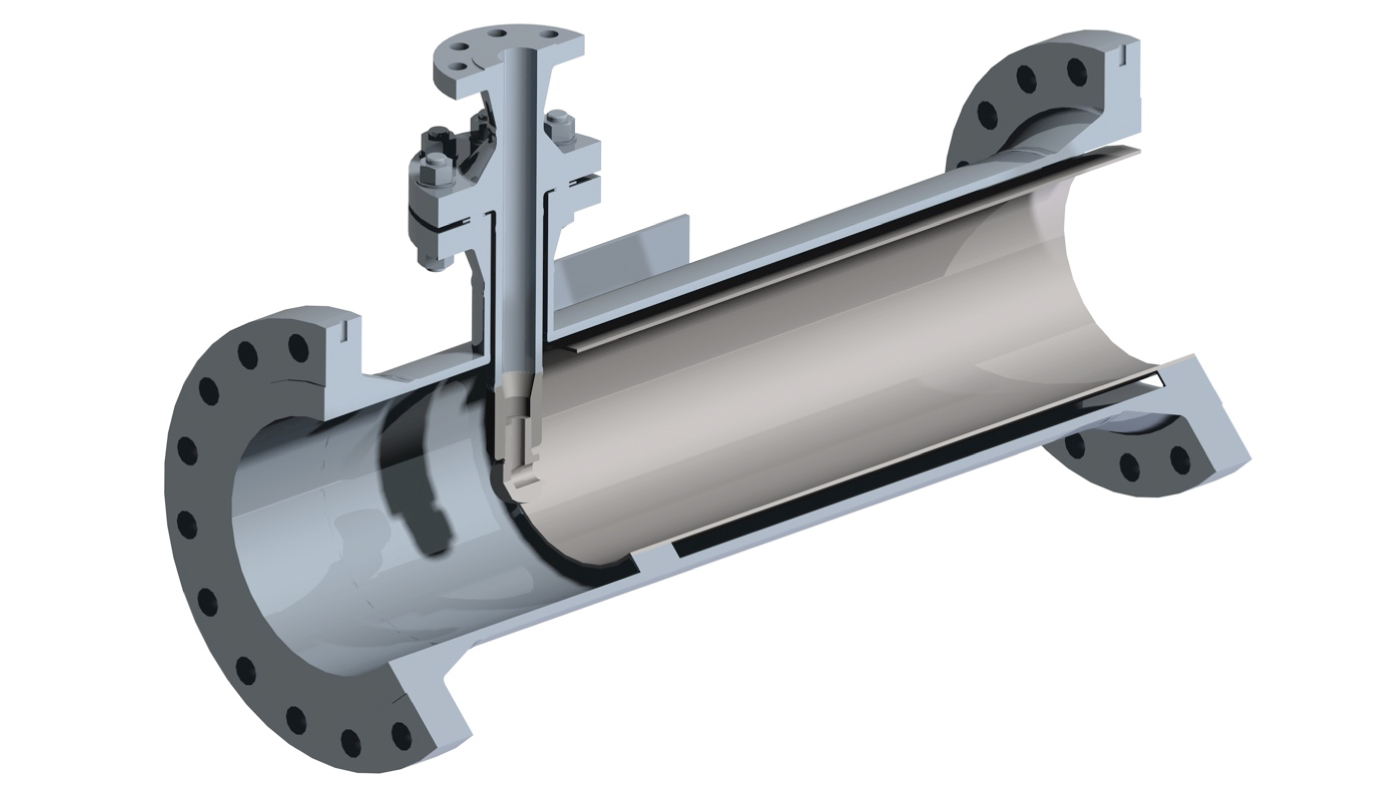

The assembly is designed for mounting on a suitable flanged branch on the steam pipework. A thermal sleeve installed downstream of the unit is recommended.

A complete unit ready for installation including spray nozzle, nozzle housing, thermal sleeve within a flanged shell.

Suitable for most general plant applications, except where high turndowns on cooling water are required.

A high-pressure auxiliary steam supply is used to atomize the incoming water within the diffuser of the unit.

The auxiliary steam pressure needs to be at least 1.5 times the inlet pressure with a minimum pressure of 3 barg.

Turndown to 20:1 or 50:1 with water recycle