Transvac’s unique Flare Gas Recovery Ejectors, are a proven solution to reduce (or even eliminate) carbon emissions as a result of widespread routine flaring and to usefully use waste gas, thereby saving energy.

Thousands of gas flares at oil production sites around the globe burn approximately 140 billion cubic meters of natural gas annually, causing more than 300 million tons of CO2 to be emitted to the atmosphere. - The World Bank

Due to environmental and legislative pressures, Operators are now looking to address the problem of flaring, with many committing to ‘Zero Routine Flaring’ initiatives. This includes many Operators, who are now demanding proven, reliable, cost-effective Flare Gas Recovery solutions to tackle greenhouse gas emissions.

Flare Gas Recovery is not a new concept, but until recently has relied upon ‘traditional’ rotating gas compression technologies such as liquid-ring or screw compressors, which are costly and unreliable. Because of this, implementation of Flare Gas Recovery solutions has been sporadic and often limited to larger facilities, where the high cost can only be justified against the recovery of very high flare gas flow rates.

To meet the goal of ‘Zero Routine Flaring’, Operators must find a more suitable, scalable, market-ready solution that can easily be applied across all of their respective production and processing facilities.

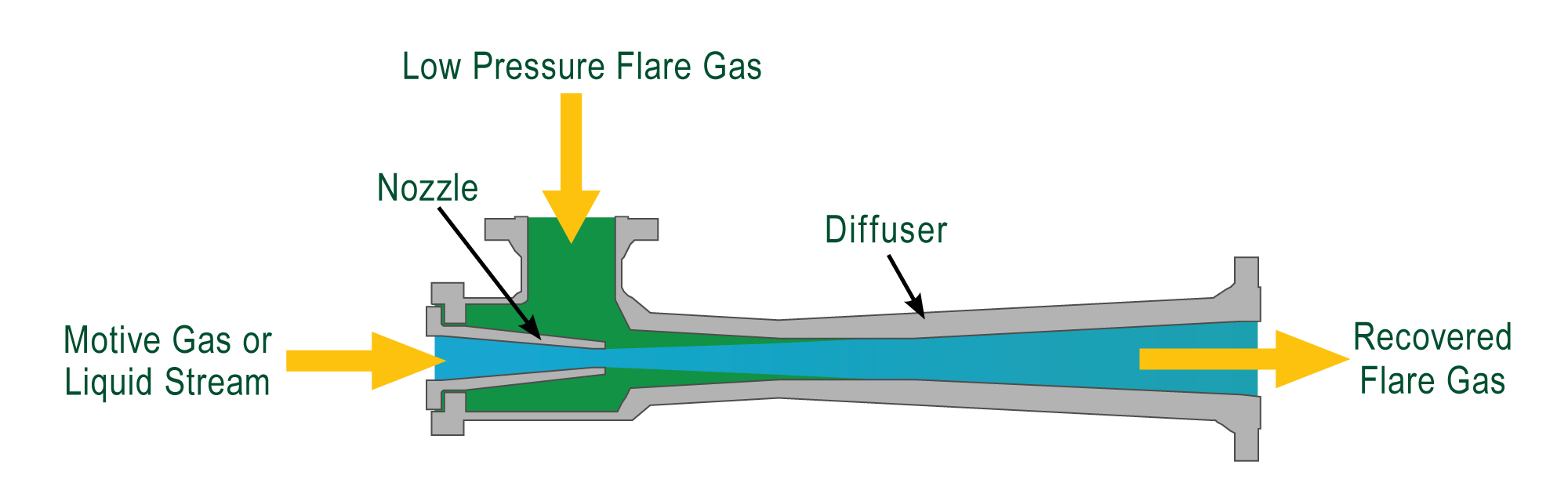

Ejectors are static, pipework-based compressors. As such, they are ideally suited to Flare Gas Recovery as they have no moving parts, require zero maintenance and can be installed in the same way as regular pipework. Their simple design makes Ejectors very cost effective when compared to traditional compressors and well suited to ‘regions of conflict’ where equipment maintenance often requires expensive security considerations.

Ejectors use a high pressure ‘motive’ stream to drive their operation. In many cases, they can utilise existing or ‘waste’ gas or liquid streams to allow them to operate. For projects where high-pressure gas is readily available, the use of Ejectors becomes a ‘no-brainer’ when compared with other gas compression technologies. This opportunity is unique to Ejectors and makes a compelling business case with respect to OPEX and CAPEX, as no ‘new energy’ is required to drive the Ejector.

Ejectors can be configured in a number of ways for Flare Gas Recovery, depending upon the process requirement and availability of existing facilities at each respective site. When considering an Ejector project, it is first important to establish the following;

…to define the required capacity of the Ejector solution.

…for the flare gas to be sent after compression through the Ejector. This determines the discharge pressure the Ejector must achieve. Typically, gas is returned to the production process at a suitable point such as a separator inlet, used as a fuel gas, or is sent down-hole.

…(and is sufficient) to provide the motive stream to the Ejector. If not, a system can be provided which includes a dedicated pump and other associated equipment, as required.

This is considered as part of the process and mechanical design, but also ensures a suitable material of construction is selected. Transvac can manufacture Ejectors from a wide range of standard and exotic materials to suit more challenging, sour service projects.

Some projects have defined modes of operation due to seasonal changes in process requirements, which can affect flare gas flow rates. Other expected variations in process need to be considered to ensure an appropriate, efficient control strategy can be employed. A robust control strategy is critical to Flare Gas Recovery projects, as it integrates with the important Flare safety system, so is always considered alongside a detailed HAZOP assessment. Transvac is very experienced and provides detailed support to end users in this regard. Transvac already has close working relationships with a number of flare specialists who can also provide expertise to mitigate any risks associated with the flares.

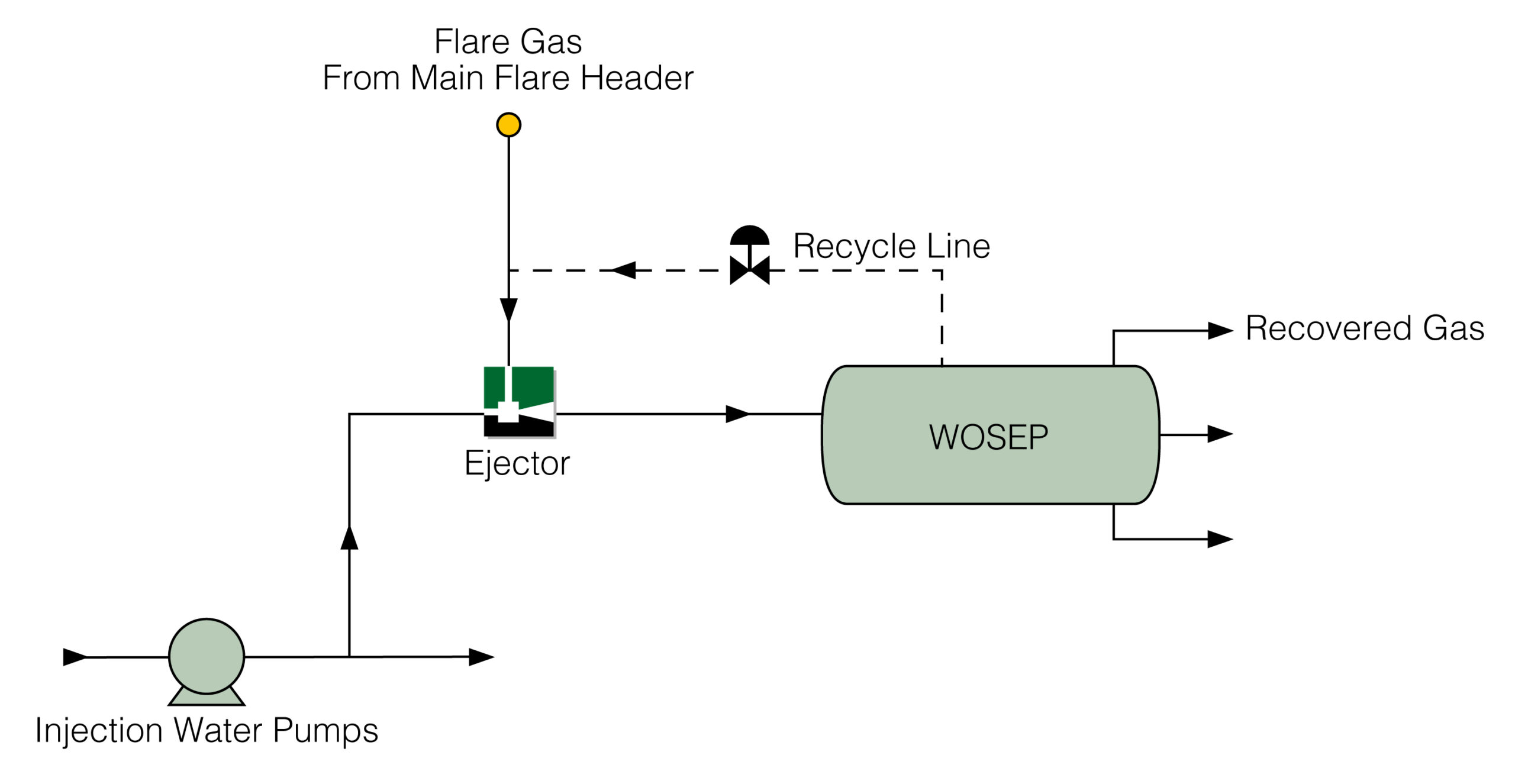

A simple Flare Gas Ejector installation in Oman.

Used to recover vent gas from storage tanks (that was previously flared), it is driven by high pressure motive water from an existing water injection pump and discharges into an existing downstream separator where the gas is recovered, eliminating emissions.

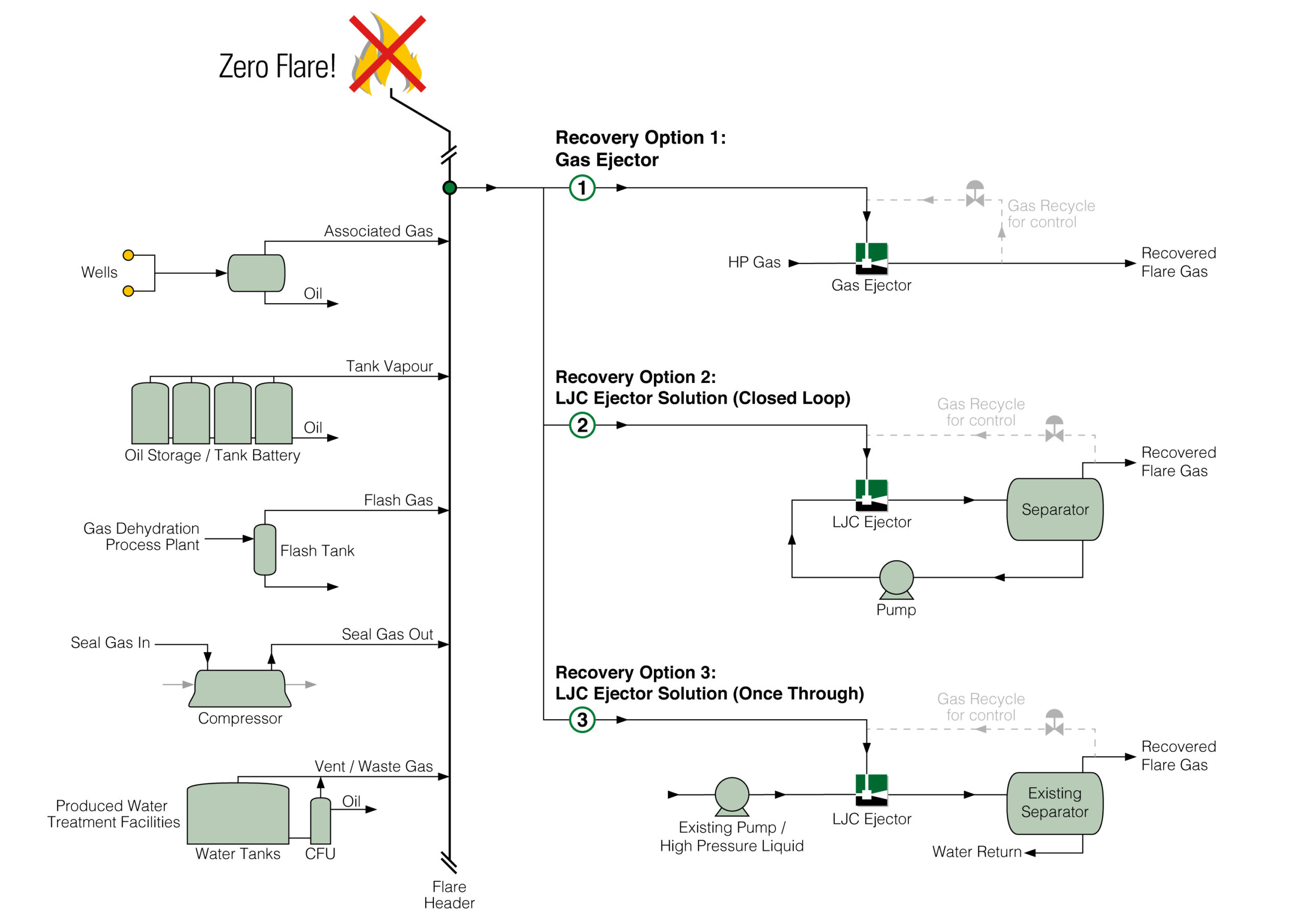

There are three common configurations for Ejector-based Flare Gas Recovery. Each option has its own unique benefits. Deciding which option is best for your project is largely based upon the availability of a suitable motive source and local facilities such as pumps or separators.

Various sources of high pressure motive gas can be used to drive a Flare Gas Recovery Ejector, including compressor discharge gas, high pressure export gas or even gas from compressor recycle, which is usually wasted.

For projects where high-pressure gas is readily available, the use of Ejectors becomes a ‘no-brainer’ when compared with other technologies. As the Ejector discharge stream is only gas, no downstream separation is required, making it a very simple installation.

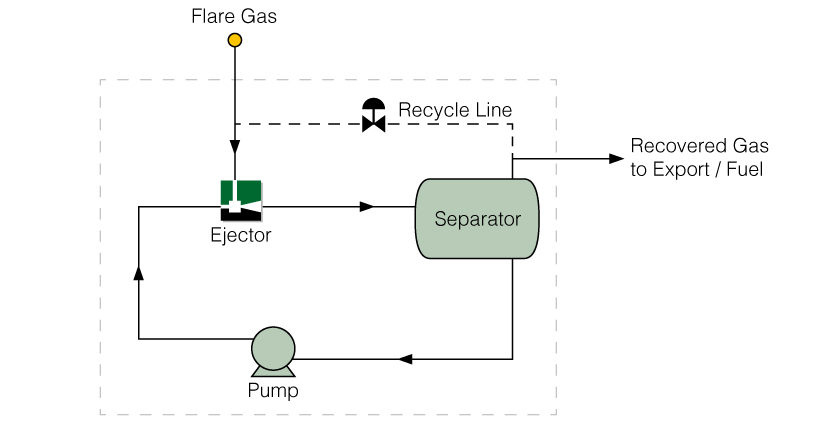

For projects that do not have the benefit of an existing suitable motive liquid stream, Transvac can provide its own, through a packaged, closed-loop system, which incorporates a dedicated pump and separator. This approach minimises liquid (typically water) requirements as the liquid is re-circulated, so is ideal for regions where water is scarce, such as the Middle-East. The Ejector discharges into a small, dedicated separator to allow recovery of the boosted flare gas flow, and also return the liquid back to the suction of the dedicated pump.

Although this is a new concept for gas compression, the Transvac Ejector is the only unique technology, all of the other system components are traditional equipment. Liquid motivated Ejector Recirculation FGR systems can be ‘standardised’ with only the Ejector internals custom made for each site conditions. They can also suitable to be offered as Rental Packages.

Many established production and process facilities have high pressure liquid streams available, such as injection or produced water and makes good sense to utilise this. In many cases only a relatively small ‘side-stream’ flow can be used to drive a Flare Gas Recovery Ejector. It is also common to utilise an existing separator for the two-phase Ejector discharge stream.

Where space or weight constraints are a consideration, such as offshore platforms or already congested facilities, Ejectors offer a valuable practical benefit. Integration with existing facilities minimises CAPEX and simplifies the scope of projects. A good example of this approach can be seen below, where Transvac supplied only the Ejector, which was tied into existing facilities, to great effect.

Transvac’s long term Product Developed Programme has been dedicated to increasing the efficiency of liquid motivated Ejectors. The results of this ongoing work have already opened up a range of new opportunities.

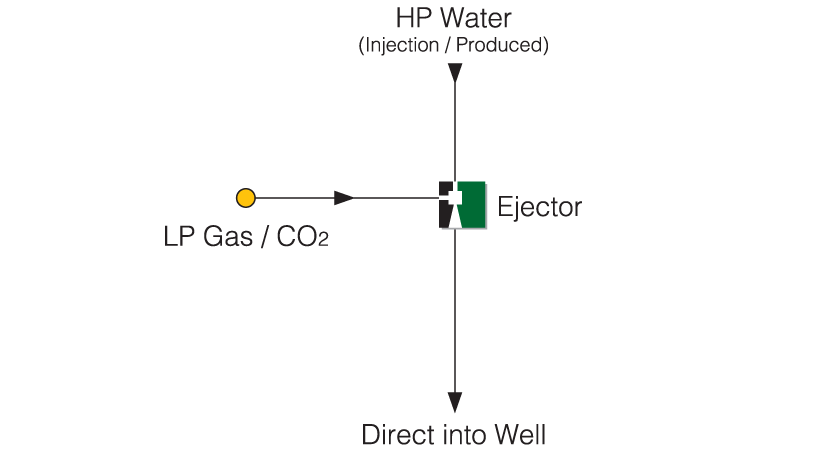

Transvac Ejectors now have the capability of achieving very high discharge pressures and can compress flare gas from 0 to 2150 psig in a single stage. This means Ejectors can now entrain low-pressure gas (such as flare gas) and discharge the multi-phase flow into an underground formation, similar to the SWAG process (simultaneous water and gas injection).

Transvac has already successfully supplied this type of system to a major Permian Operator in the USA, where the gas was very sour (40% H2S).

Due to the increased efficiency of Transvac’s liquid motivated Ejectors, motive flow requirements have decreased significantly.

Transvac can now offer packaged recirculation systems, complete with a dedicated pump, which use less power than traditional compression equipment and offers far greater reliability, at a lower cost and with faster project lead times.

When considering the use of Liquid Motivated Ejectors, the first step it to identify a suitable liquid stream at the site. This will vary from one facility to another, based upon the various processes being carried out.

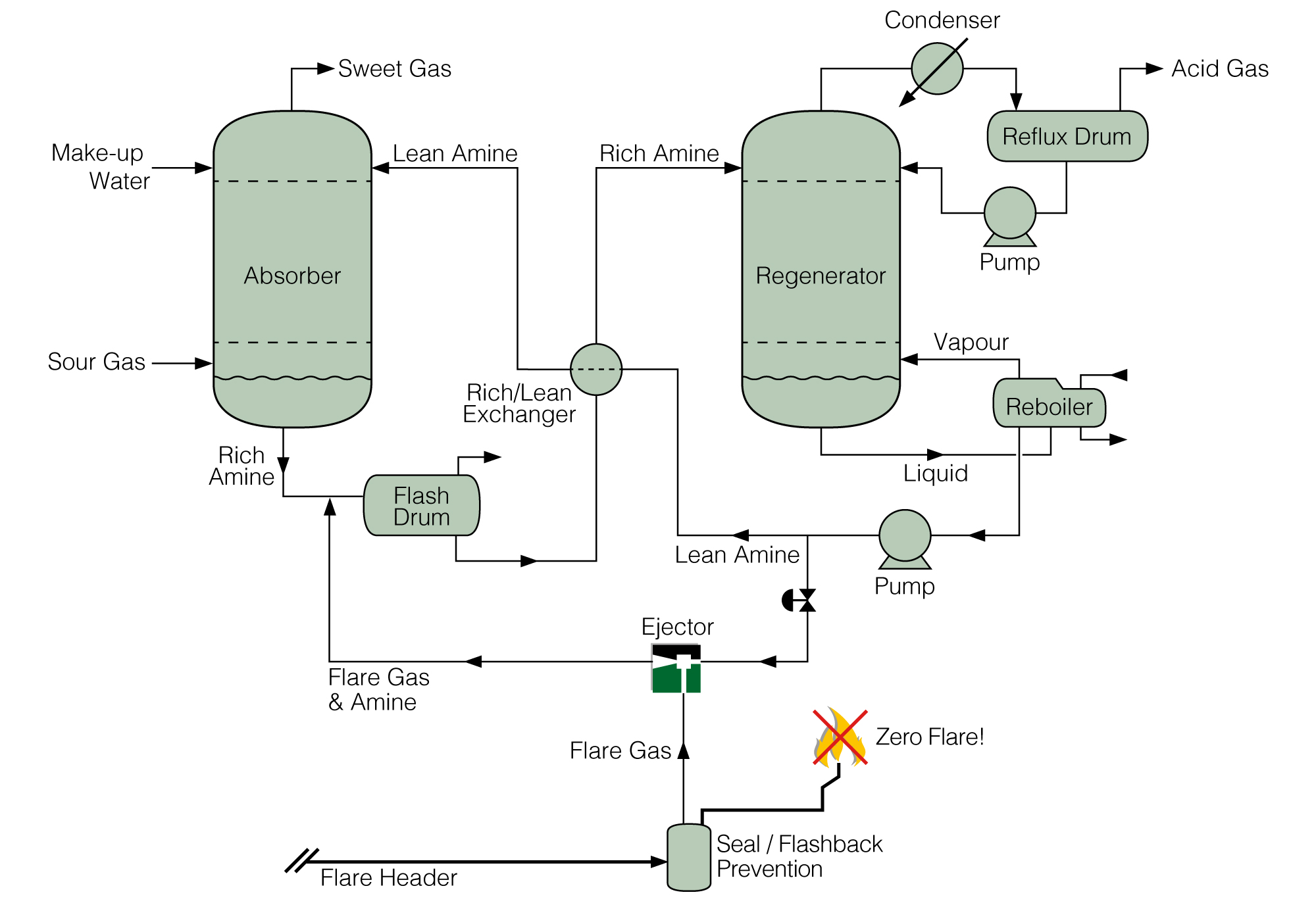

Aside from water streams (produced / injection etc), another suitable fluid is Amine. Lean or Rich Amine is often readily available at gas processing facilities where gas sweetening is carried out.

The Amine recirculation pumps typically provide a sufficient motive stream to drive an Ejector. In this way, Flare Gas can be recovered back into the process.

In this example, the flare gas is taken upstream of the seal drum / flashback prevention in the Main Flare Header and returned into the Gas Sweetening Unit before the Absorber flash drum. The ‘borrowed’ Amine is returned to the Gas Sweetening Unit for regeneration, as usual. The now-compressed flare gas can be directed to gas processing, rather than its previous destination, the flare burners.

This Flare Gas Recovery Ejector was manufactured from Duplex Stainless Steel due to the sour flare gas stream.

It was installed skid mounted, complete with all instrumentation and controls to handle fluctuations in Flare Gas flow during operation. It is driven by an existing injection water stream and discharges into an existing water/oil production separator.

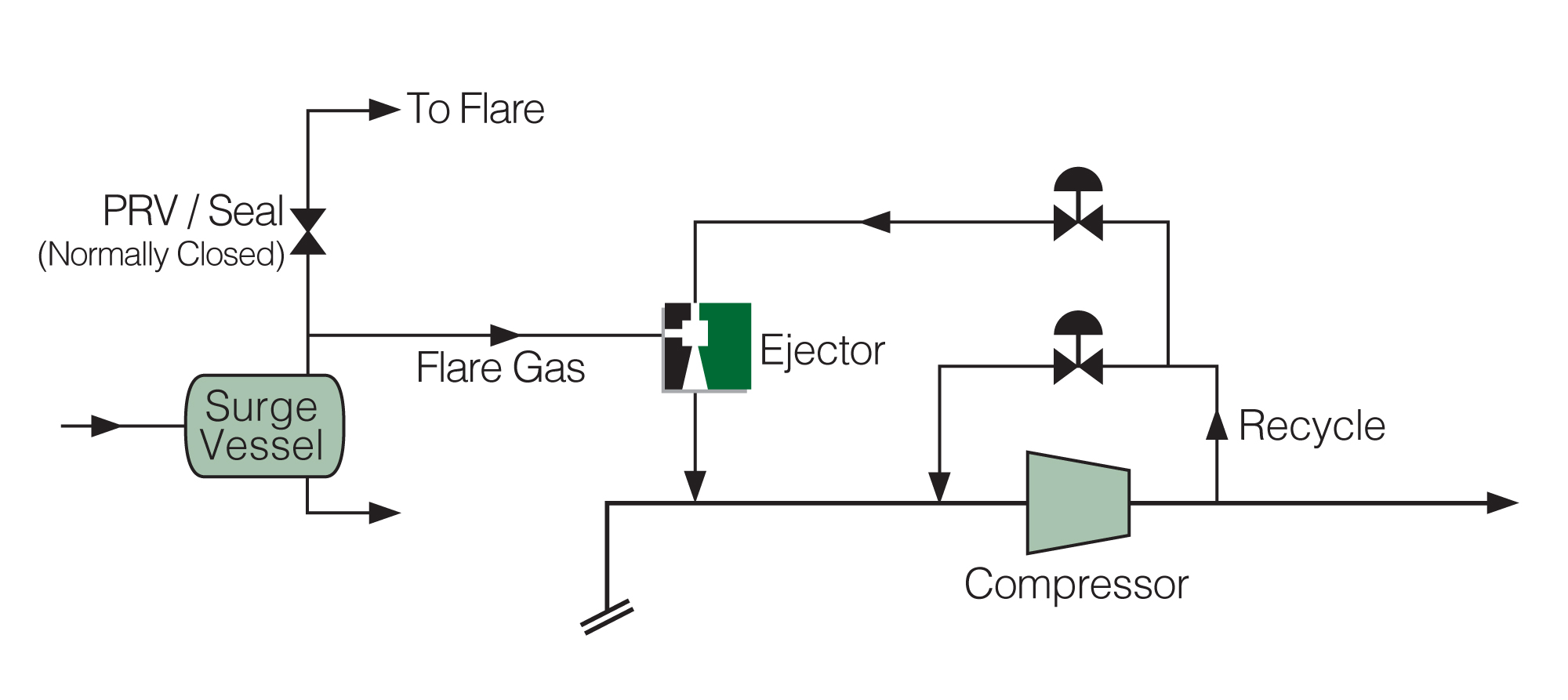

Transvac Gas motivated Ejector can compress flare gas from 0 to a maximum of 115 psig in a single stage. However, much higher gas compressions can be achieved by multi-stage Ejectors.

Waste gas energy can be used to drive Ejectors. For example: Gas energy that is normally wasted when an existing mechanical Compressor is in recycle can be used to drive a gas Ejector to entrain and recover flare gas (or boost production of Wells).

Globally there are 1000’s of existing mechanical Compressors in recycle with waste energy available to be used productively.

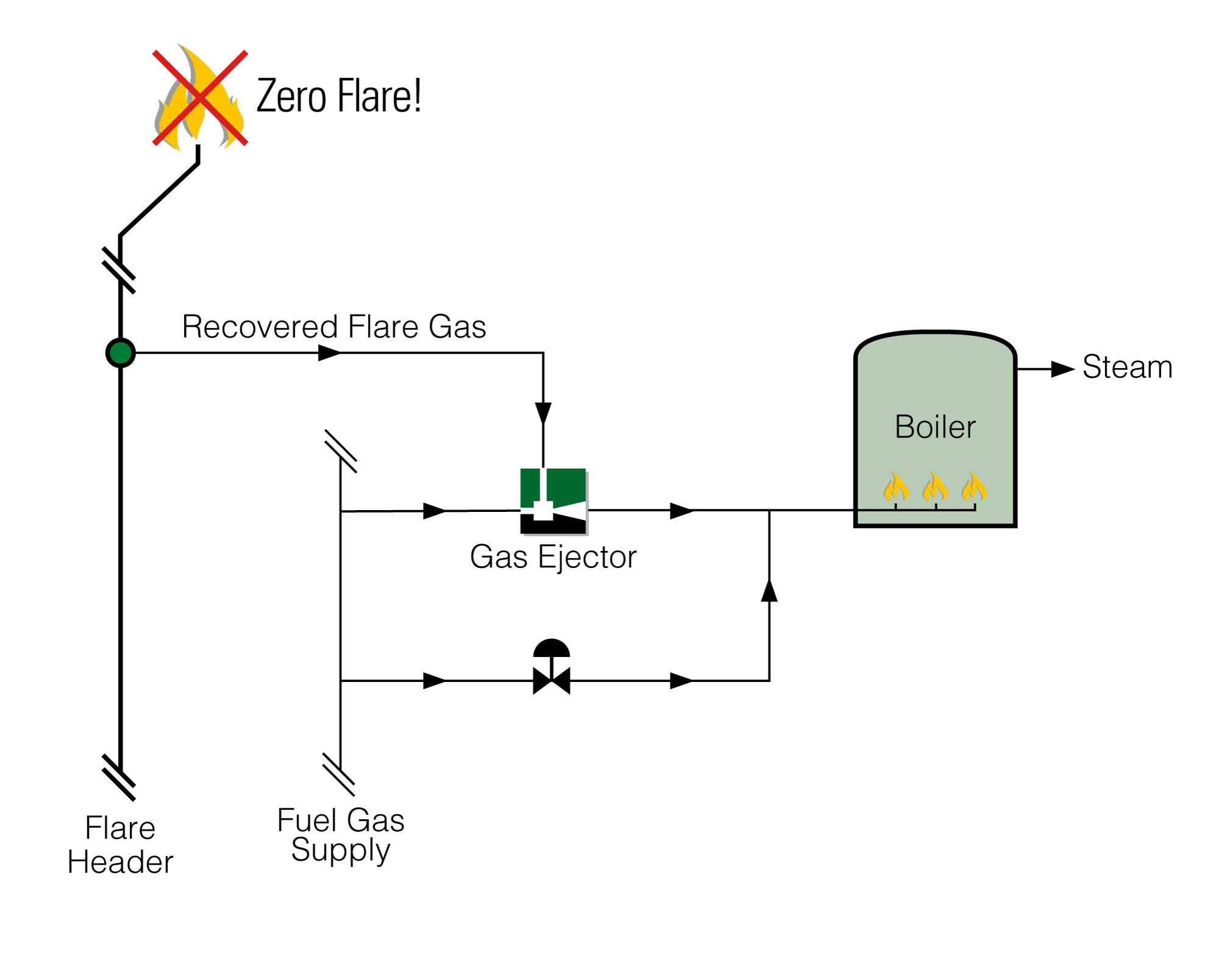

Fuel Gas or other sources of motive gas be used by an Ejector to entrain and compress flare gas. The discharge gas can be used as a fuel for Boiler Burners or Gas Engines thereby monetising the flare gas recovery process.

“South Ghawar Producing Department (SGPD) garnered the award for its innovative Flare Gas Recovery System (FGRS), which has the potential to be a game-changer in the oil and gas industry.SGPD’s project was selected out of more than 600 submissions from all over the world. The award was just the latest in a series of honors bestowed upon SGPD for its unique design that is tailored to gas-oil separation plants (GOSPs).

The solution has resulted in significant cost-avoidance, and the recovery of nearly all flared gas, reflecting positively on Saudi Aramco’s environmental stewardship. Conventional systems use a compressor to recover the flared gas, and the compressor needs auxiliaries such as drums and coolers. Such a complex system is not economical, with a payback period approaching 10 years.

Saudi Aramco’s innovative design capitalizes on the specifics of the company’s GOSP design, and matches these with the characteristics of an Ejector to recover the flared gas. High pressure injection water, which is available from the discharge of the water injection pumps, is used to boost the pressure of the gas recovered from the flare header by using a two-phase ejector. The mixture of the gas and water is sent to an existing water oil separator, where the gas is recovered in the gas compression system.

This approach, which has not previously been used in GOSPs worldwide, limits the need for new equipment – to just an ejector and a flare seal drum – with simple controls. The ejector-based system is promising in terms of low cost, simple operation, and convenient control. Furthermore, the elements in the design are typical for oil processing facilities worldwide, making the scope of the application global”