Transvac Mining Ejectors are an ideal solution for transporting sand, slurries or nodules as part of a mining process. Using pressurised water as the motive fluid, mining Ejectors entrain solids through its suction ports and transports these solids at a high velocity to the point of application. This is commonly a separator, where the solids are separated from the liquid.

All Transvac Mining Ejectors are custom designed to meet the unique process requirements of each client and their individual application. With no moving parts and no maintenance, Transvac’s Ejector technology offers unmatched reliability for mining applications when looking to entrain solids into a liquid stream.

To ensure trouble-free operation, all Transvac Ejectors are designed, manufactured and NDT tested in-house. Transvac can also carry out CFD-based FAT testing in-house.

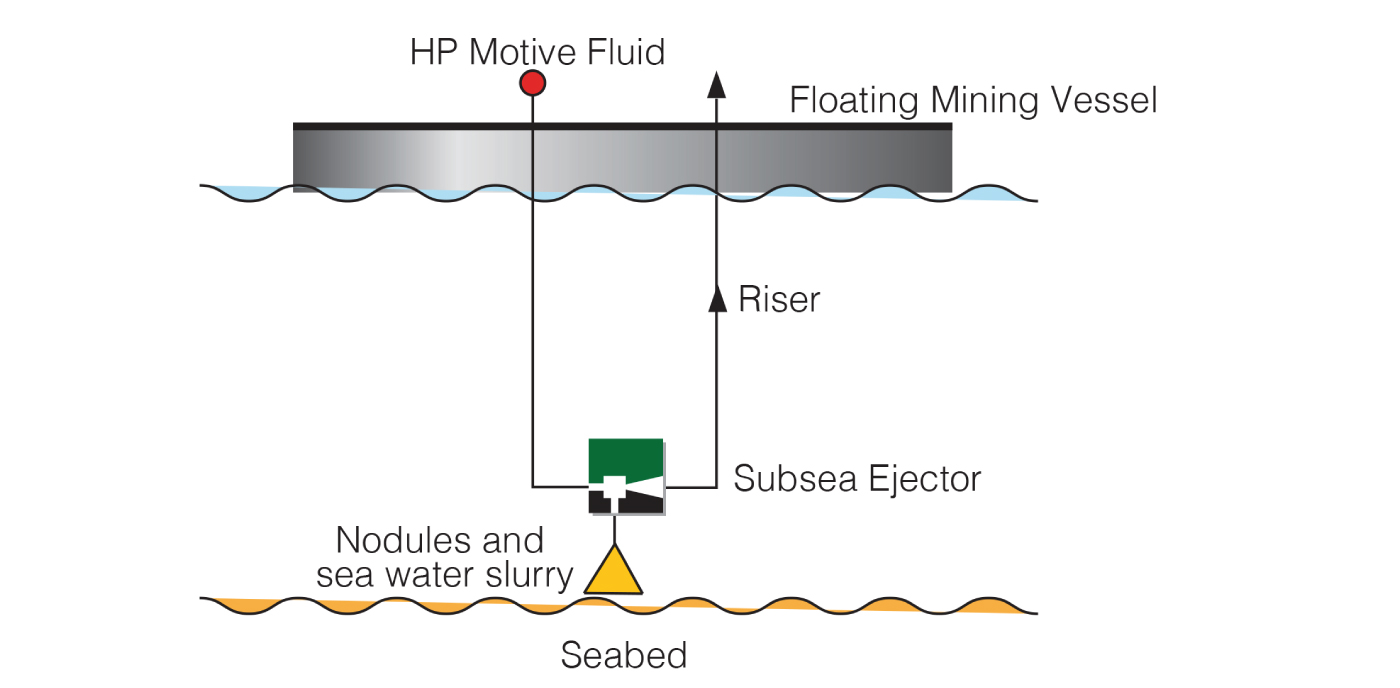

A typical subsea mining application using an Ejector

Transvac Mining Ejectors are tailor made for the specific processes of the mining industry – more specifically in the mineral extraction process where the slurry is taken from a large pit and subsequently transported back to the surface.

Where Mining Ejectors are to be integrated into larger processing packages or modules, Transvac can customise the Ejector design as required to ensure space limitations are addressed, without reducing process performance.

Rotating mechanical equipment can be troublesome and expensive in subsea or mining production systems. Reciprocating compressors and reciprocating pumps require huge amounts of energy, often megawatts of power. Ejector technology can often operate using existing energy and therefore operating costs can be negligible. Ejector flows can be simply calculated using pressure drop data across the Ejector, thereby negating the need for flow metering instrumentation, which provides further cost savings.

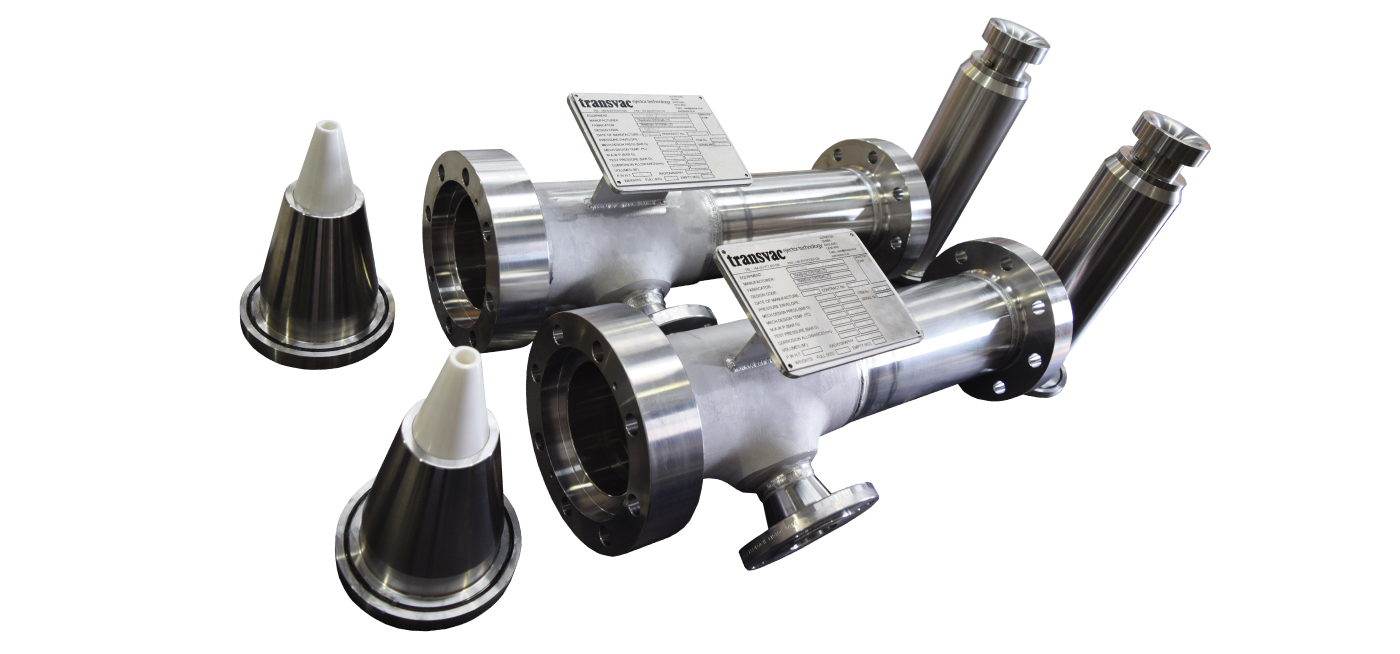

Custom designed Ejectors for mining/mineral extraction process.

Mining applications require special consideration when selecting appropriate materials of construction. Transvac provide guidance and alternative material options based upon our experience of each application.

Many of our mining Ejectors are supplied with a special grade ceramic nozzle and diffuser components, to withstand the abrasive nature of these applications.

We can also fabricate from other materials as required. For more information on materials of construction, please visit our Materials page here.

Ejectors shown with ceramic internal parts to resist the effects of abrasion

Transvac have successfully achieved ‘Technology Readiness Level 7’ status for Subsea Ejector technology and have an extensive reference list of proven installations worldwide for various Oil and Gas and Mining applications.

Ejectors are ideally suited to operate in this harsh environment. This is due to the robust design and reliability offered through having no moving parts.

Further information on our Subsea Ejectors can be found here.

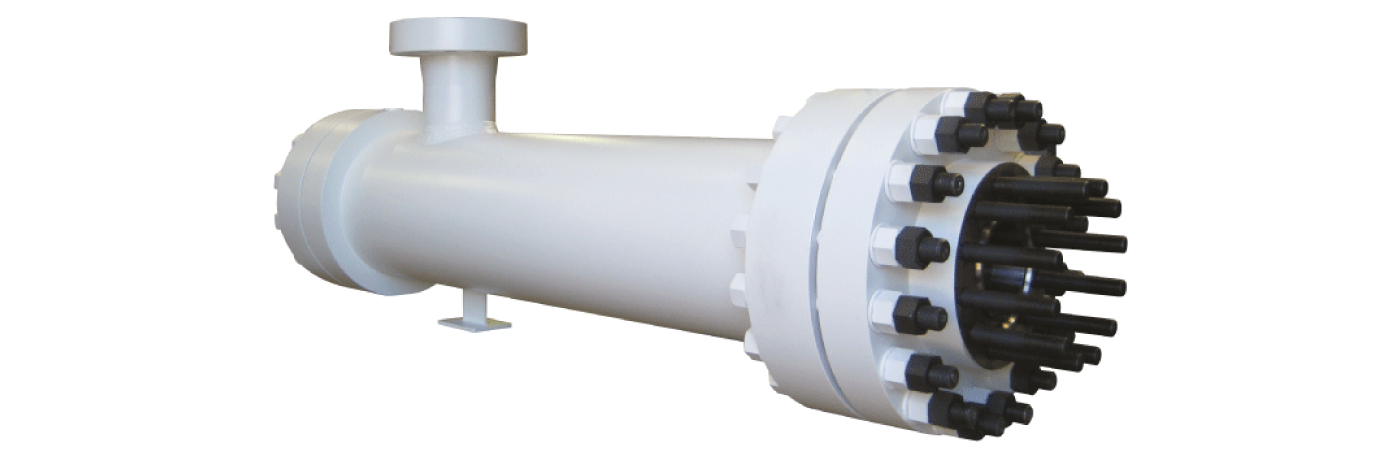

A Multi-Channel Subsea Ejector