With no moving parts and no maintenance, Transvac’s Ejector technology is an ideal solution for subsea processing and FPSO applications. To ensure trouble-free operation, all Transvac subsea Ejectors are designed, manufactured and tested in-house. Operating rotating mechanical equipment can be troublesome in subsea production systems. Reciprocating Compressors and Reciprocating Pumps require huge amounts of energy, often megawatts of power. Ejector technology can operate using existing energy and therefore operating costs can be negligible. Rotating mechanical equipment also requires special designs for performing subsea.

Ejector designs change very little whether subsea or topside. In some applications, Ejector flows can be simply calculated using pressure drop data across the Ejector, thereby negating the need for flow metering instrumentation.

Materials of construction and mechanical design meet project specific piping standards and are fully qualified. Transvac also provides ceramic nozzle and diffuser components for abrasive applications which have been proven over many years on topside applications.

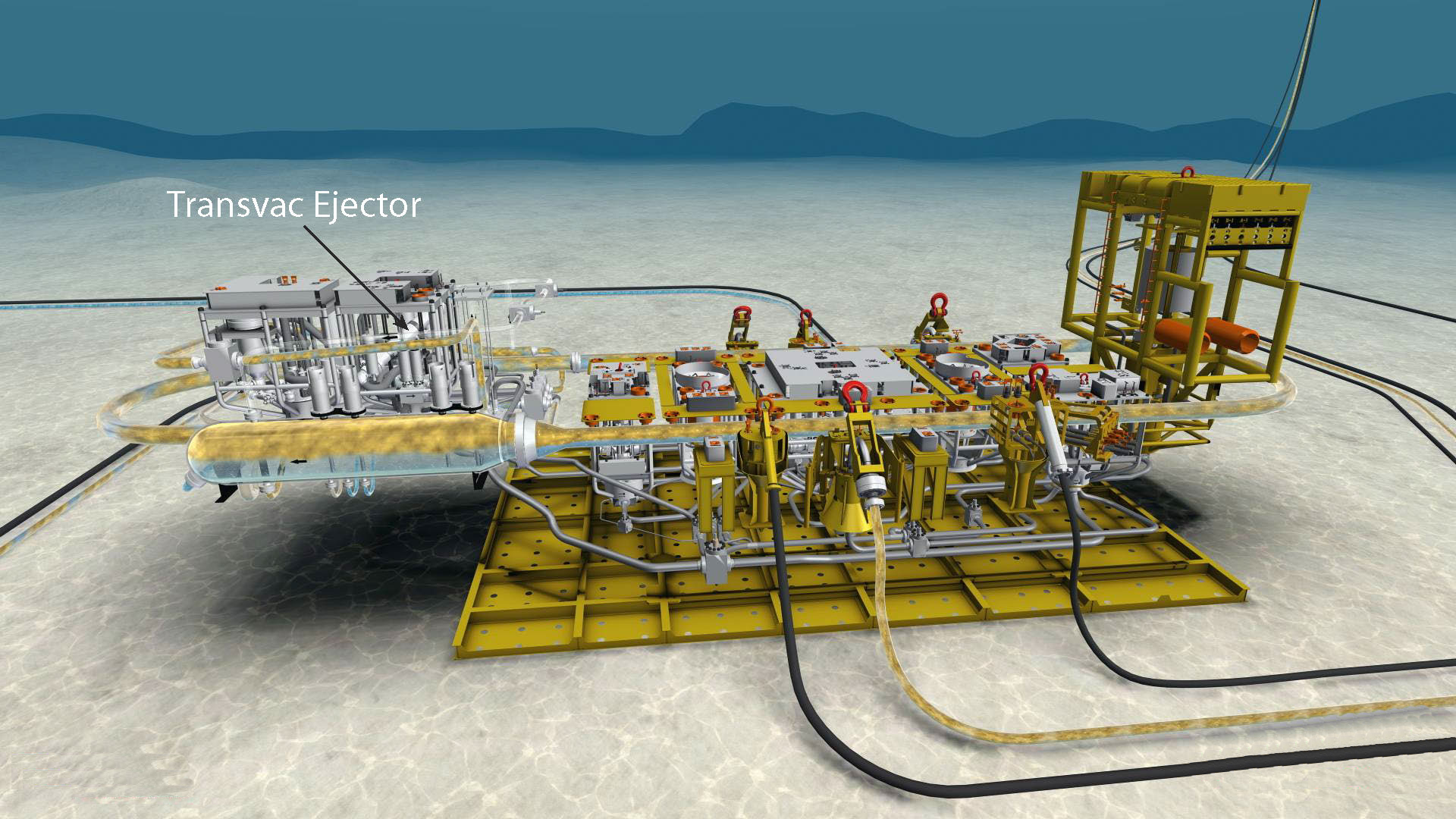

One of the Transvac Ejectors installed on the Marlim Subsea Processing Module

Most technologies require significant modification to operate in a subsea environment. By contrast, due to the simple, pipework-based design, Ejectors do not.

This means that they can be used for a wide range of applications, including;

Transvac Ejectors have successfully achieved ‘Technology Readiness Level 7’ status. This is the highest quality assessment to attain, meaning our Ejectors are FULLY PROVEN to work in a Subsea oil and gas production field.

Our first Subsea project was for Statoil (now Equinor) via FMC Technologies, for their Tordis Subsea Processing Module. The project was a World’s first to achieve improved oil recovery, subsea separation, boosting, and injection (SSBI).

Ejector supplied for Tordis Project

Multi-Channel Ejector supplied for Marlim Project

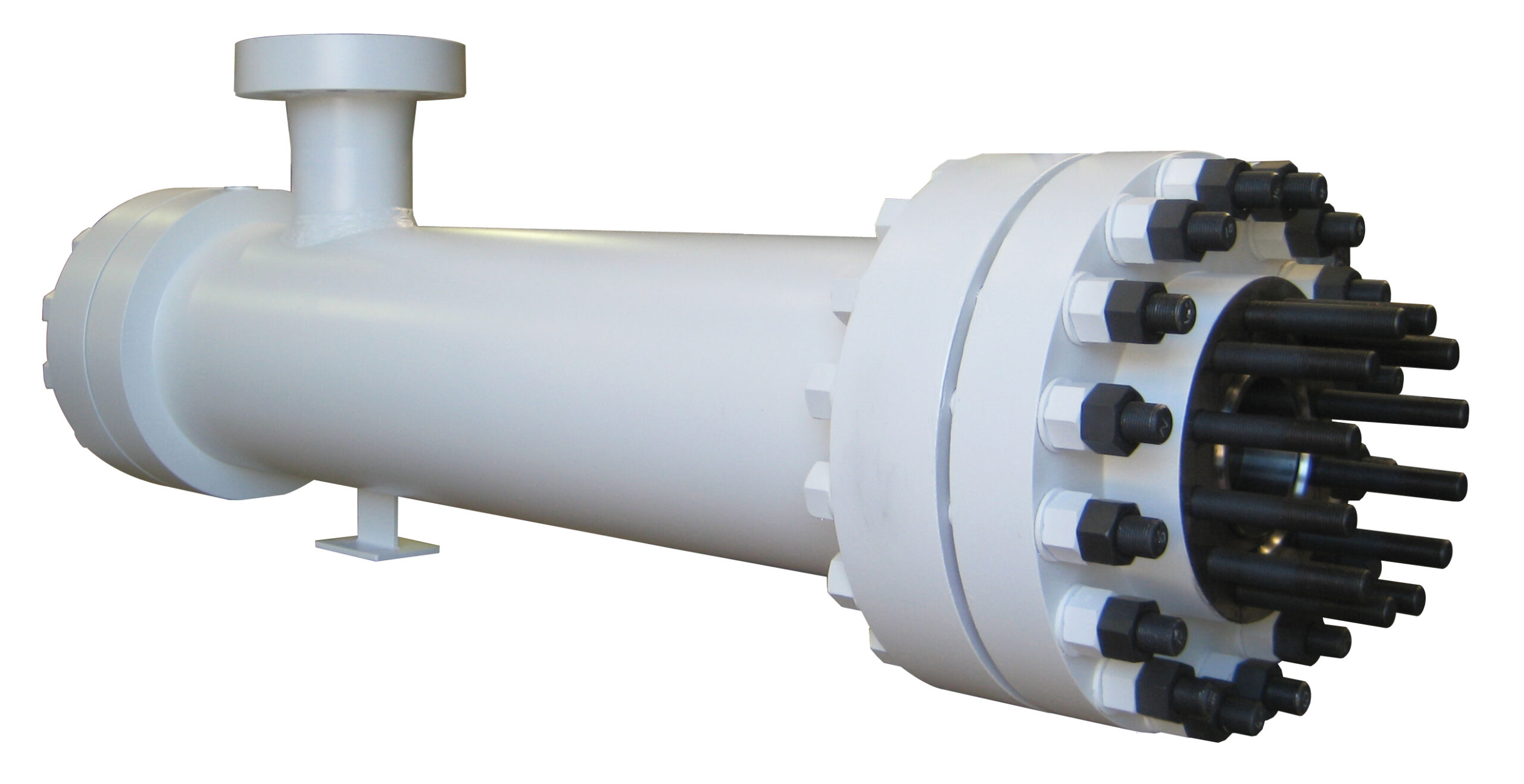

Block-body type Ejector supplied for Marlim Project

The Petrobras Marlim project consists of a subsea separation system designed to separate water from oil, gas and sediments and re-injects the separated water into the water reservoir. The oil, gas and sediments are then routed to the host platform topside.

The separation system is now installed in Marlim field, which is located in Campos Basin, at a water depth of 870m.

Transvac completed a comprehensive test program for Petrobras/FMC Technologies, for Multi-channel pressure boosting and flushing Ejectors (Subsea Jet Pumps). These multi-channel Ejectors included special ceramic wear-resistant internals and underwent full flow performance mapping using Transvac’s R&D facility flow loop system.

CFD was used to steer and validate the novel Ejector design. This was carried out in partnership with ‘real’ world’ rig testing.

The compact, multi-channel Ejector design was required to allow the Ejector to fit inside the processing module as shown.