Transvac Steam Ejectors can be designed specifically for Sulphur (Sulfur) Pit applications where a slight draught is required to remove sulphurous gases from tanks and storage areas.

To prevent sulphurous solids from forming within the Steam Ejector bodies, Transvac offers partial or full steam jackets. A typical sulphur-recovery steam-jacketed Ejector can be seen below.

Various materials of construction are available with exotic materials available to minimise corrosion and improve the lifetime of the Ejector nozzles.

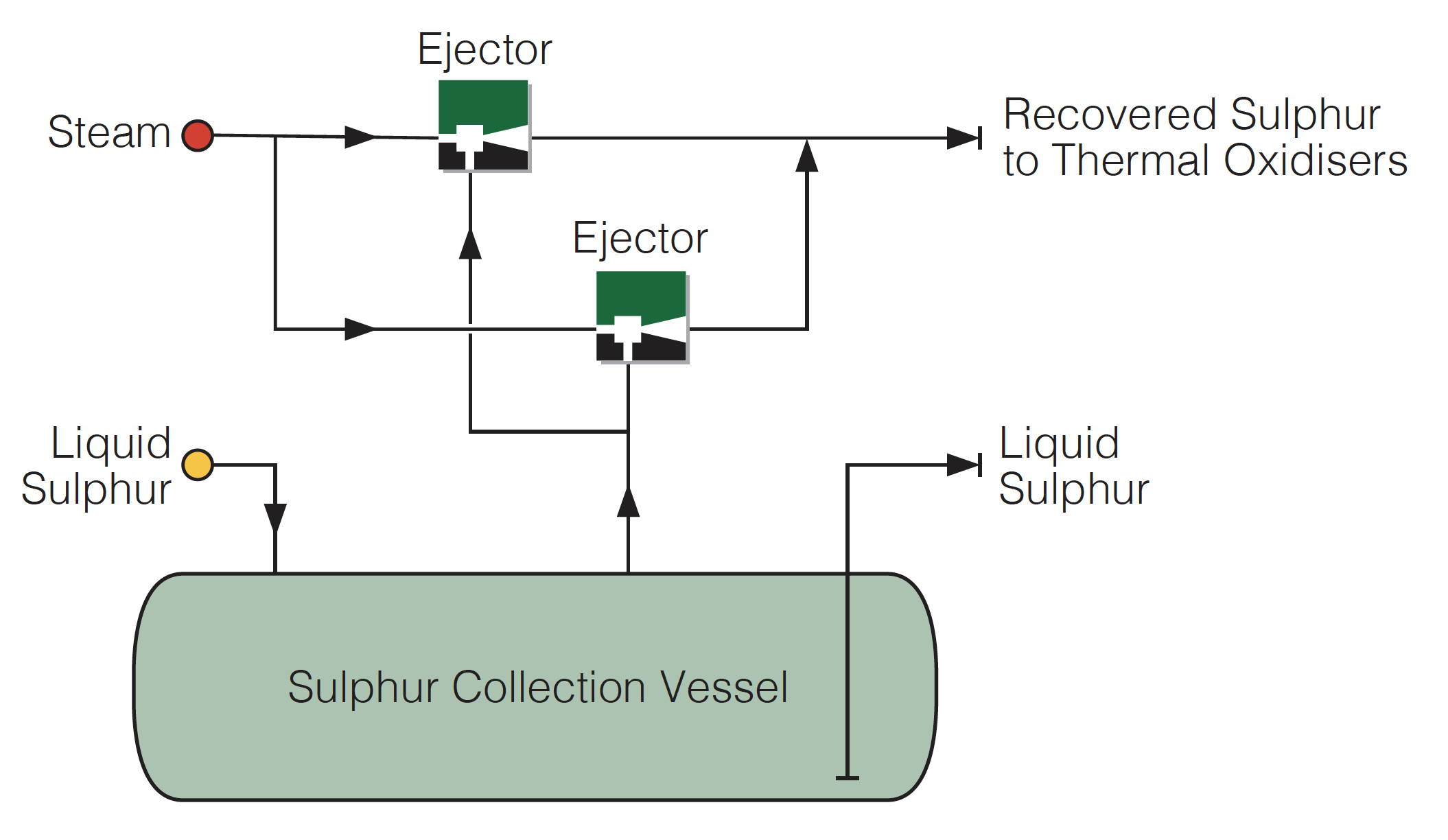

A typical sulphur recovery process, using steam Ejectors.

This example shows two Ejectors in parallel.

Typical steam-jacketed Sulphur Recovery Ejectors