Transvac offer a range of ejector-based technologies designed for tank heating applications.

Tank heating involves heating fluids in storage tanks, either above or below ground. It is used in a multitude of manufacturing and industrial processes. Tank heating is necessary when fluids require heating for processing or when a fluid’s viscosity is temperature dependant.

Some fluids require heating to move though processes in applications such as Slurry mixing and Slurry pumping. Tank heaters are also often used to prevent fluid freezing, maintain temperatures and prevent condensation.

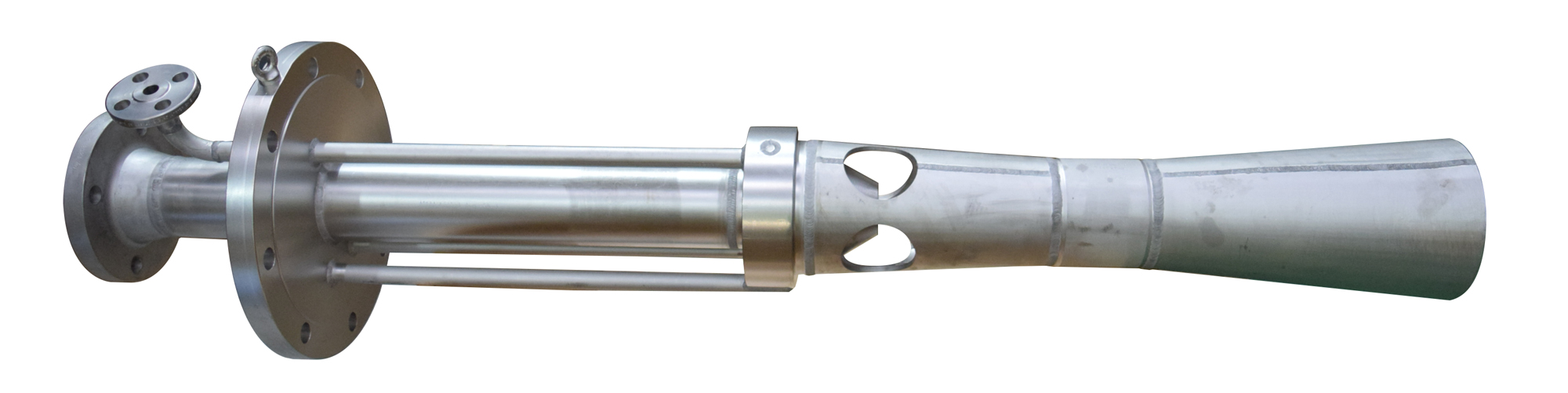

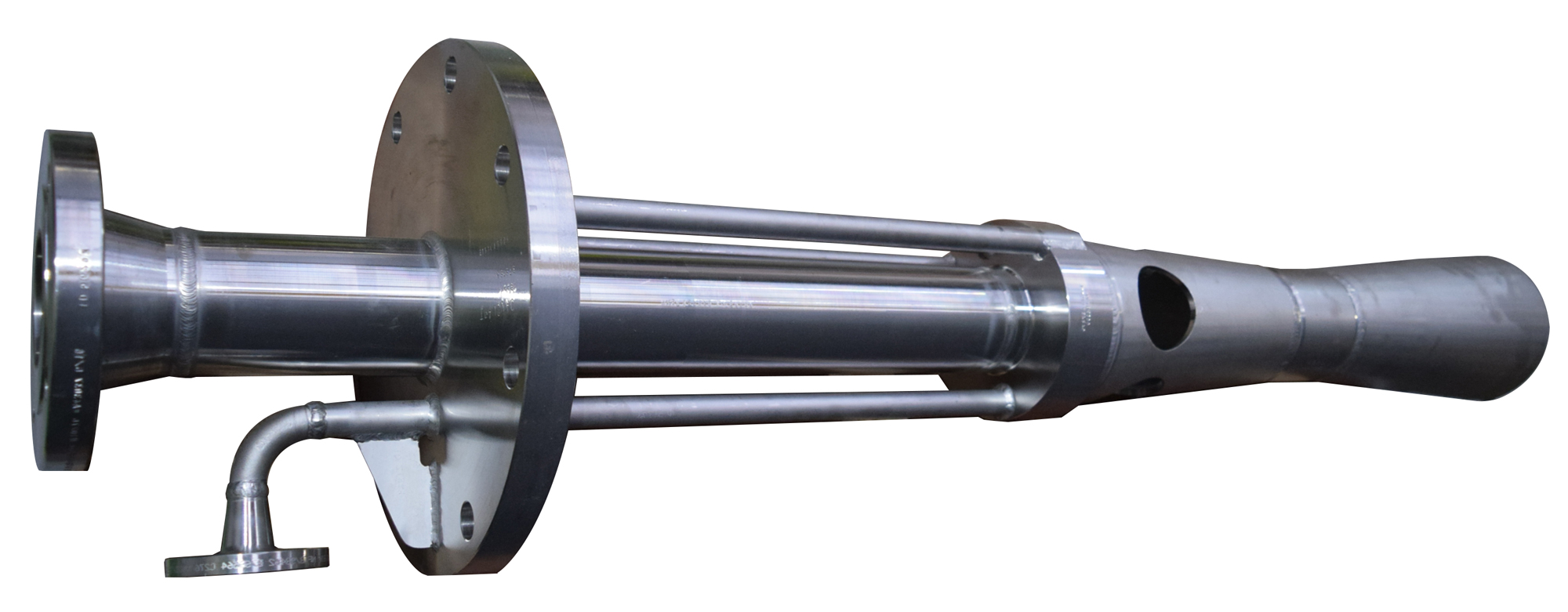

Transvac’s range of Direct Injection Heaters (DIH’s) are used to silently heat fluids in tanks. For in-line heating please see our Instantaneous Jet Heaters page. Maximum efficiency is maintained by bringing the process fluid and steam into direct contact, utilising both the sensible and latent heat.

Transvac’s DIH’s work by accelerating steam through a motive nozzle, this entrains liquid from the surrounding area of the tank, into which the steam condensates. The hot liquid is then discharged creating tank turnover/mixing.

All of our tank heating systems are built to process specifications to ensure maximum operating efficiency. Each heater is manufactured as a single unit and is installed directly on the tank connection (thru-wall type) or onto a manifold.

Alternatively, if units cannot be placed within a tank, an Instantaneous Jet Heater can be used as part of a liquid recirculation system.