Tank Jet Mixers are mass momentum exchange devices. They use pressurised liquid energy, provided by an external recirculating Pump, to entrain, mix and pump a secondary in-tank liquid, to achieve bulk mixing.

Importantly, our Tank Jet Mixers have no moving parts. This provides unrivalled reliability, giving you complete peace of mind.

Operators choose this reliable technology for many applications across multiple industries including;

This includes blending, solids suspension, dilution, heat distribution, pH control, temperature control and homogeneity.

In operation, pressurised motive liquid is discharged through the Jet Nozzle into the suction chamber. The change from pressure energy to kinetic energy (velocity) creates a region of low pressure that entrains liquid from within the Tank via open suction ports.

The motive and suction liquid streams combine and mix under high shear conditions in the Jet Mixer Diffusers and the resulting intimately mixed fluid is discharged into the bulk of the Tank liquid as high velocity turbulent jets.

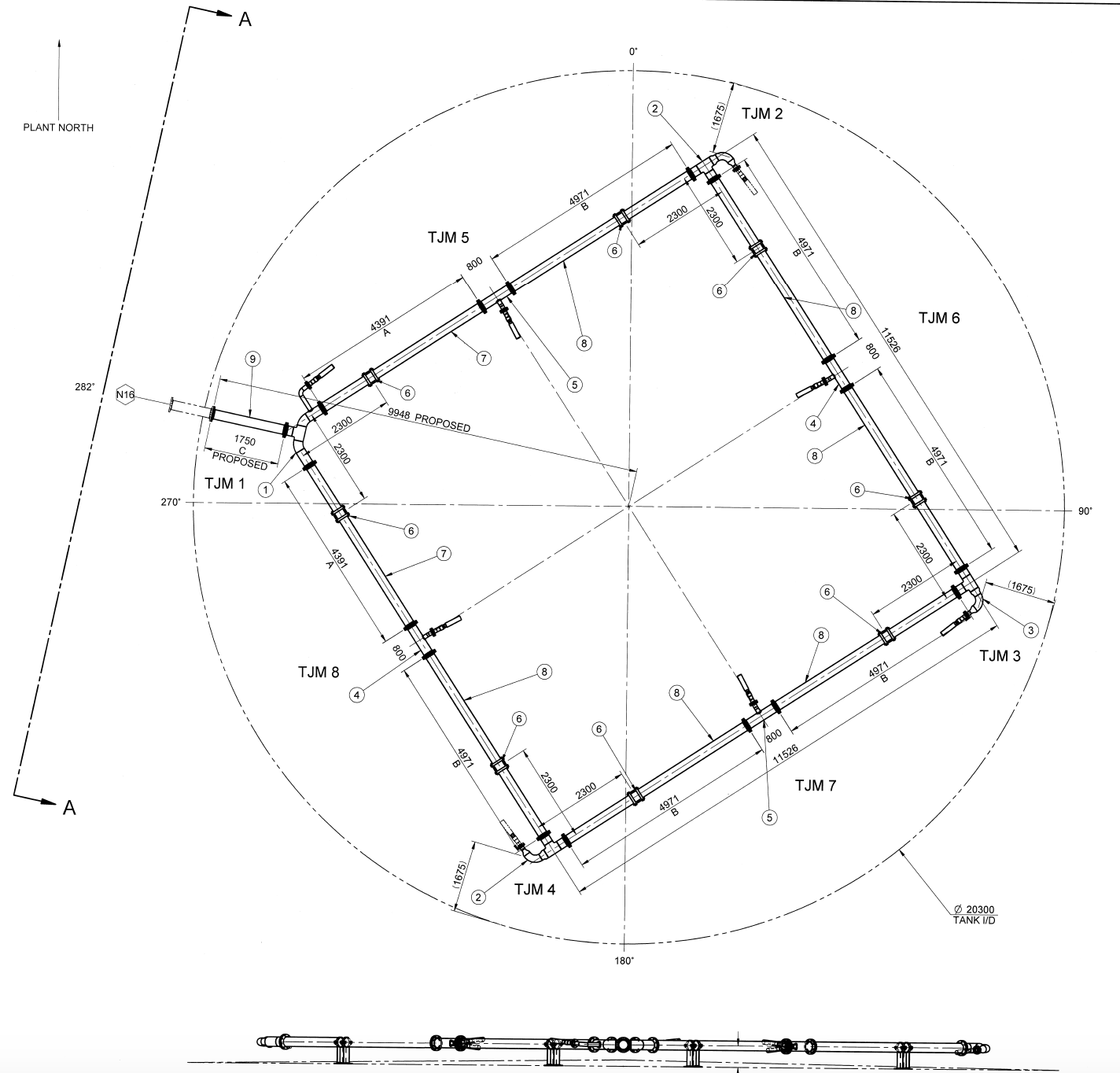

Each Tank Jet Mixing system is custom designed to suit the mixing requirements. We offer both single or multiple Jet Mixer arrangements, as required.

Transvac Jet Mixers are often supplied with an angle-creating, flanged spool to direct flow through a Tank wall or are mounted on an in-tank manifold to evenly distribute the mixing energy.

Standard Transvac Tank Jet Mixing systems entrain 3-parts suction liquid for every 1-part motive liquid.

The size, number of Jet Mixers required, and system layout depends on the Tank volume, mixing time, temperature, liquid compositions and mixing duty.

Transvac can supply Jet Mixers only with support spools or in-tank manifolds. Alternatively, Transvac can provide manifold designs, which can be made locally.

Tank Manifold Design

Stainless Steel Tank Jet Mixers

Tank Mixers can be manufactured in virtually any material, carefully chosen to suit the process conditions;

Hygienic designs are also available for the food / pharmaceutical industry as required.

CFD modelling is perfectly suited to studies concerning Tank Mixing Solutions. Transvac can offer a detailed CFD analysis to optimise the arrangement of Jet Mixers in tanks to avoid fluid bypassing or stagnation.

Transvac can assess the quality of mixing based on various installation options, including manifold layouts; Jet Mixer inlet elevations; and angles. This is particularly beneficial for larger tanks where stagnation can be difficult to predict without CFD.

More complex studies can be undertaken focusing on the mixture’s physical properties as well as fluid concentrations.

Learn more about our CFD capabilities here.