Transvac Offers Steam System Support to Legacy Systems

Due to a significant reduction in the number of Steam Ejector suppliers servicing the process industries, many end users are experiencing difficulties in maintaining and upgrading existing Steam Jet Vacuum Systems.

Using expertise and experience gained over 46 years as a designer and manufacturer of Steam Ejector Systems, Transvac is in a unique position to address this problem.

Transvac offers a service to investigate operational problems and can offer solutions for all types of Steam Ejector systems, even if they were originally supplied by another manufacturer. This service can also include training for the end user’s engineering staff and periodic ‘health checks’ on system performance.

- System leakage / air ingress

- Blockages

- Cooling systems poor performance / failure

- Internal & external wear

- Corrosion & cracking

An inefficient vacuum system will inevitably cost clients money. Ignoring problems may eventually result in a more serious plant failure or outages, potentially causing a complete shutdown. If a client is happy with their existing system, it may still be worth Transvac engineers coming out to assess any potential for an increase in performance.

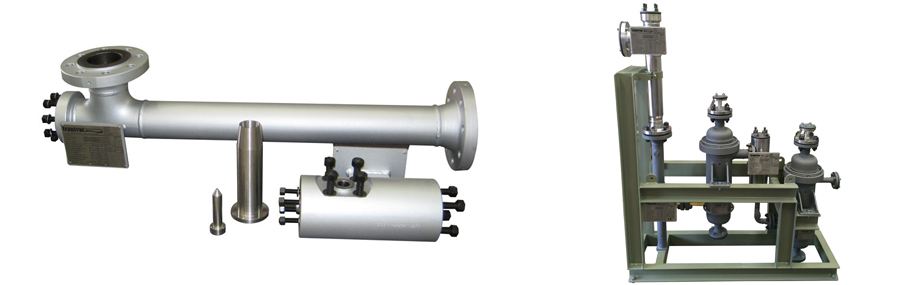

Steam spares to keep your system flowing

If steam becomes wet, this can eventually cause damage to the inside of the Ejector, affecting performance. Transvac can manufacture spare nozzles and diffusers to ensure the efficient operation of steam Ejectors at all times. Re-issue internals for existing Transvac units can be manufactured quickly, but Transvac can also provide new internals for legacy, non-Transvac Ejectors. By working with the client, new drawings can be designed to retro-fit into existing systems, providing security for clients who may have systems with no supporting manufacturer.

If you would like to find out more about our Steam troubleshooting service, please click here or contact us.