Vent Gas & Vapour Recovery using Ejectors

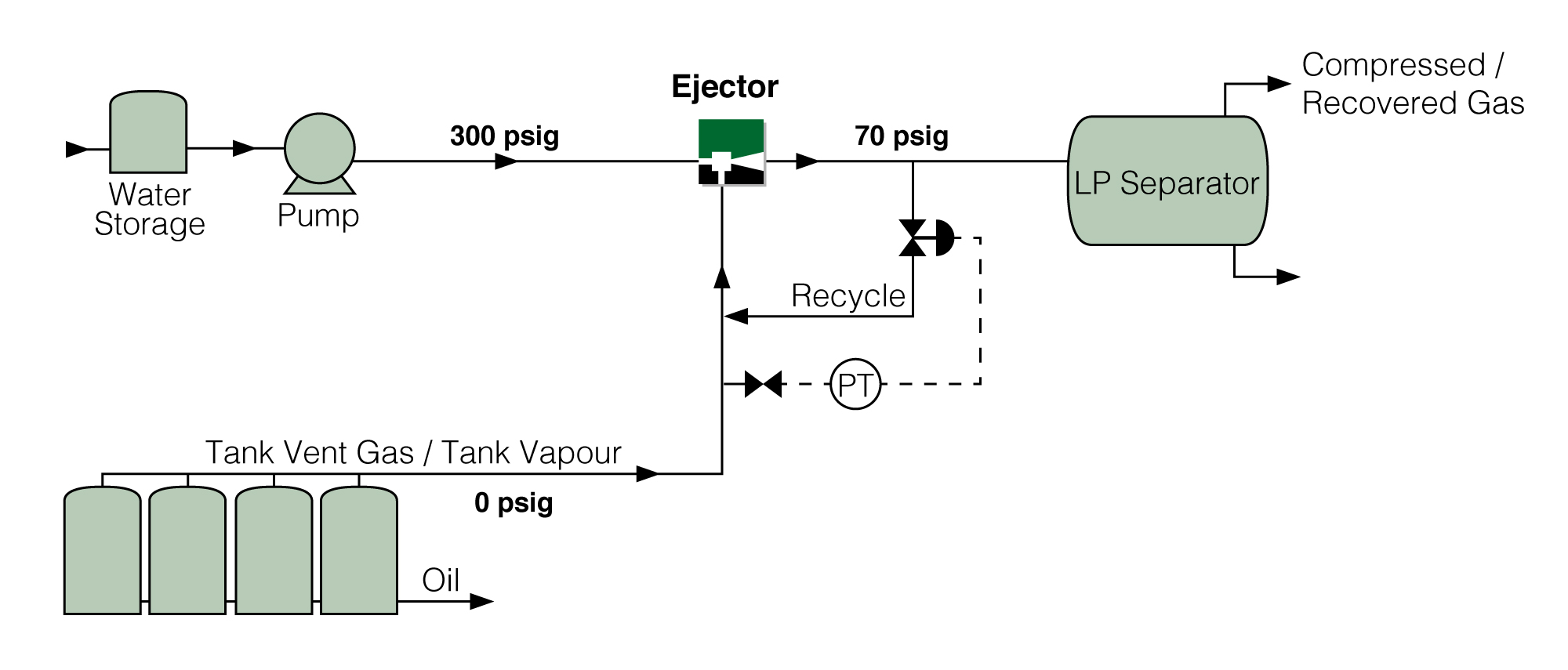

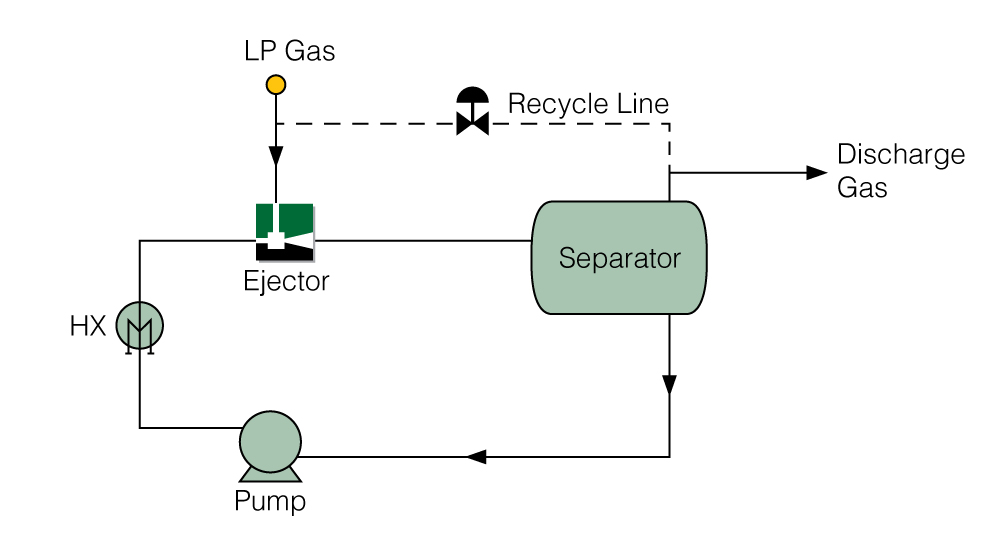

We have a long history of supplying Ejectors for Vapour Recovery (VRUs) and Vent Gas Recovery. Similar to our Flare Gas Recovery Ejectors, our Vent Gas and Vapour Recovery Ejectors can use Liquid or Gas as the motive stream. These Ejectors typically operate at low / atmospheric suction pressures, but have the ability to discharge the recovered gas to a destination with a far higher pressure if required.

Vent and Vapour Gas can often contain harmful VOC’s, so it is vital that the recovery system is safe and reliable – with no maintenance requirements. With no moving parts, Ejectors are ideally suited to this duty, to eliminate fugitive emissions that can lead to unsafe operating conditions.

Transvac Ejectors are driven by high-pressure motive fluids (usually water or gas), which are used to entrain and compress low-pressure suction vapours to an intermediate discharge pressure.